Moving on up (the value chain): How producers can get more value from every tonne

20.10.2025The demand for high-quality sand and aggregates continues to grow, but variability in recycled and natural materials can limit profitability. In today’s increasingly competitive market and ever-evolving regulatory landscape, producers need to create as much value as possible from every tonne processed.

AggPulseTM wet density aggregates separator

AggPulseTM wet density aggregates separator

© CDE

This will be the focus of an upcoming webinar on Wednesday 22nd October when wet processing experts from CDE will outline how producers can unlock greater value from their sand and aggregates by improving material quality, reducing waste, and boosting profitability.

The 45-minute session will highlight how CDE’s equipment line – including its latest innovation, the AggPulseTM wet density aggregates separator, as well as its CFCUTM density and sizing classification system, and ShearCleanTM attrition cells – are helping operators move materials up the value chain.

CFCUTM density and sizing classification system

CFCUTM density and sizing classification system

© CDE

Discussions will be led by senior product development engineer Leigh Moore with regional insights from Joseph Teahl, CDE’s business development manager for the US, and Thibault Vandecaveye, who will provide a European perspective.

ShearCleanTM attrition cells

ShearCleanTM attrition cells

© CDE

Equipment spotlight

By forcing pulsating air through a water-immersed bed of C&D waste, CDE’s AggPulse agitates and separates material fractions based on density. While lighter contaminants float to the top for separation, heavier material settle in the bed of the unit ensuring valuable aggregates continue through the process for further washing and sizing.

CDE’s CFCU provides an effective system for removing lightweight contamination from fine material fractions. Water is then removed from the CFCU underflows on the dewatering screens, and the clean sand is then stockpiled.

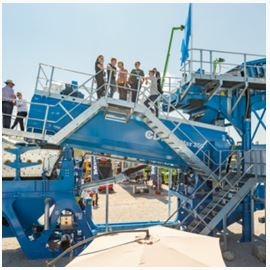

The demand for high-quality sand and aggregates continues to grow

The demand for high-quality sand and aggregates continues to grow

© CDE

The webinar will also feature CDE’s ShearClean Attrition Cells, a patented technology designed for unrivalled contaminant removal from fine material feeds. With a unique paddle design that maximises material-on-material impact, ShearClean delivers consistent scrubbing performance to produce high-quality, in-spec sands. Its efficient design reduces power demand and operational costs, while robust features such as rubber-lined cells and an integrated oil cooling system ensure long-term reliability and maximum up-time.

Producers need to create as much value as possible from every tonne processed

Producers need to create as much value as possible from every tonne processed

© CDE

CDE business development manager Thibault Vandecaveye said: “With waste streams becoming increasingly dirty and complex, integrating CDE’s CFCU, ShearClean, and AggPulse technologies has been transformative for our customers operations. The integration of CDE’s CFCU and ShearClean technologies at sites like Entreprise Spiess or Freehaven has unlocked new levels of efficiency in fines recovery and contaminant removal from sand fractions, allowing materials to be upgraded and reintroduced into the value chain. With the addition of AggPulse to a washing process, valuable aggregates an also be separated from the dirtiest waste streams. It’s a game-changer for moving material up the value chain. This webinar will showcase how these innovations are driving circularity and profitability in modern waste recycling or aggregates washing operations.”