Nordbau 2025: Liebherr presents construction machines for a wide range of applications

08.09.2025Nordbau is one of the most important construction trade fairs in Northern Europe. It offers a comprehensive range of products for building construction and deep foundation, commercial vehicles as well as machinery for municipal and environmental technology. Liebherr is presenting a selection of its construction machines at booth N 224 in the northern outdoor area. On display are the LRB 19 piling and drilling rig with the LV 23 high-frequency vibrator from the deep foundation product segment. From the earthmoving product segment, visitors will be able to see the A 911 Compact wheeled excavator and the L 506 Compact wheel loader. In the pavilion of the 300 m² booth, Liebherr will also provide information about the remanufacturing programme. This programme for earthmoving and material handling focuses on the reuse of existing components, such as engines, gearboxes and hydraulic pumps.

The Liebherr LRB 19 piling and drilling rig is a compact all-rounder in deep foundation. It is exhibited at the booth in combination with the LV 23 vibrator

The Liebherr LRB 19 piling and drilling rig is a compact all-rounder in deep foundation. It is exhibited at the booth in combination with the LV 23 vibrator

© Liebherr

Compact all-rounder in deep foundation: LRB 19 piling and drilling rig with LV 23 high-frequency vibrator

The LRB 19 handles even the toughest of deep foundation jobs with ease. The piling and drilling rig combines precision and efficiency. The 450 kW motor and the BAT 180.1 drilling drive with a maximum torque of 180 kNm provide the necessary power for drilling with Kelly equipment, double drill heads, full displacement equipment and soil mixing.

Liebherr is presenting the LV 23 vibrator to visitors at the trade fair. The high-frequency vibrator drives steel sheet piles, steel pipes and other pile-driving elements into the ground, or pulls them out again. It is attached to the carrier machines from the LRB series and provides the necessary pulling and pushing force through the feed systems. Thanks to the hydraulic quick coupler, the various attachments of the LRB 19 can be changed easily without tools and without having to leave the cab. All hydraulic, mechanical and electrical connections are automatically coupled. The improved hose guide also optimises the workflow.

The LRB 19 has a self-assembly system for the ballast. This can be raised easily by the LRB 19’s leader. This means that no additional crane is required for the setup. The Liebherr assistance systems for deep foundation applications increase safety and efficiency. The work area restriction helps the driver to monitor the turning range, jib length and equipment height (height adjustment). As soon as it attempts to move into the previously set restricted area, it stops automatically, thus preventing potential collisions. The LIPOS positioning system uses modern satellite technology to assist in the precise alignment of attachments during drilling or pile-driving operations. The drilling assistant automates the concreting process during continuous flight auger drilling. The vibratory compaction process is also automated thanks to the vibration assistant.

The new wheeled excavators impress with their combination of sophisticated machine design and user-friendly operation. Due to their robust construction and high performance, they are particularly suitable for efficient work

The new wheeled excavators impress with their combination of sophisticated machine design and user-friendly operation. Due to their robust construction and high performance, they are particularly suitable for efficient work

© Liebherr

Compact, versatile, powerful: A 911 Compact wheeled excavator makes work more effective

The strengths of the A 911 Compact really come into their own in confined spaces. Its small tail swing radius (1.60 m) and front swing radius (2.10 m) make the wheeled excavator extremely manoeuvrable. The powerful engine is offered with either 55 kW or 80 kW output and, depending on the version, is equipped with an SCR system and after-cooler. The sensitive hydraulics and intuitive controls guarantee high precision and enormous digging forces. This allows for a high material-handling performance and productivity on construction sites in inner-city areas with limited space and in gardening. When combined with various attachments, the A 911 Compact is extremely versatile.

The robust undercarriage design with integrated travel drive offers tremendous acceleration thanks to its high traction force. The high driving speed reduces transport time, which increases productivity and saves costs. The Speeder version allows speeds of up to 37 km/h. Liebherr’s standard tyres, which are available in several versions, such as dual tyres, ensure maximum stability. When visitors open the comfortably designed cab, they can see how much space it offers for driver-specific adjustment of the operating elements. The standard INTUSI (Intuitive User Interface) operating system allows the operating functions to be arranged individually.

The compact loaders combine high performance with safety, and are also flexible in terms of application and use

The compact loaders combine high performance with safety, and are also flexible in terms of application and use

© Liebherr

A machine for every application: L 506 compact loader impresses with its great price-performance ratio

Powerful, secure and flexible: The manoeuvrable L 506 Compact is ideal for applications in road construction and gardening, deep foundation and civil engineering, as well as in municipal services and for rental fleets. The compact and low design results in a particularly low centre of gravity, which ensures high payloads and increases stability and resistance to tipping. The hydrostatic Liebherr travel drive is extremely robust and powerful, enabling smooth acceleration without noticeable gear changes and without interrupting the traction. For even faster order processing, the L 506 is also available as a Speeder version with a maximum speed of up to 30 km/h. For versatile applications, the optionally available Solidlink hydraulic quick coupler with an integrated, automatic hydraulic coupling system allows different attachments to be changed in seconds – easily at the touch of a button from the cab. In addition, Liebherr’s control lever allows all working and driving functions to be controlled precisely and safely.

The modern cab design allows to work with greater concentration and reduced fatigue. The displays, controls and driver’s seat are perfectly coordinated and form an ergonomic unit. Large glass surfaces extending down to the foot area ensure greater safety in the work area and excellent all-round visibility. The entire engine compartment is covered by a single hood, making it easily accessible. Maintenance can be carried out from the ground, which significantly reduces downtime.

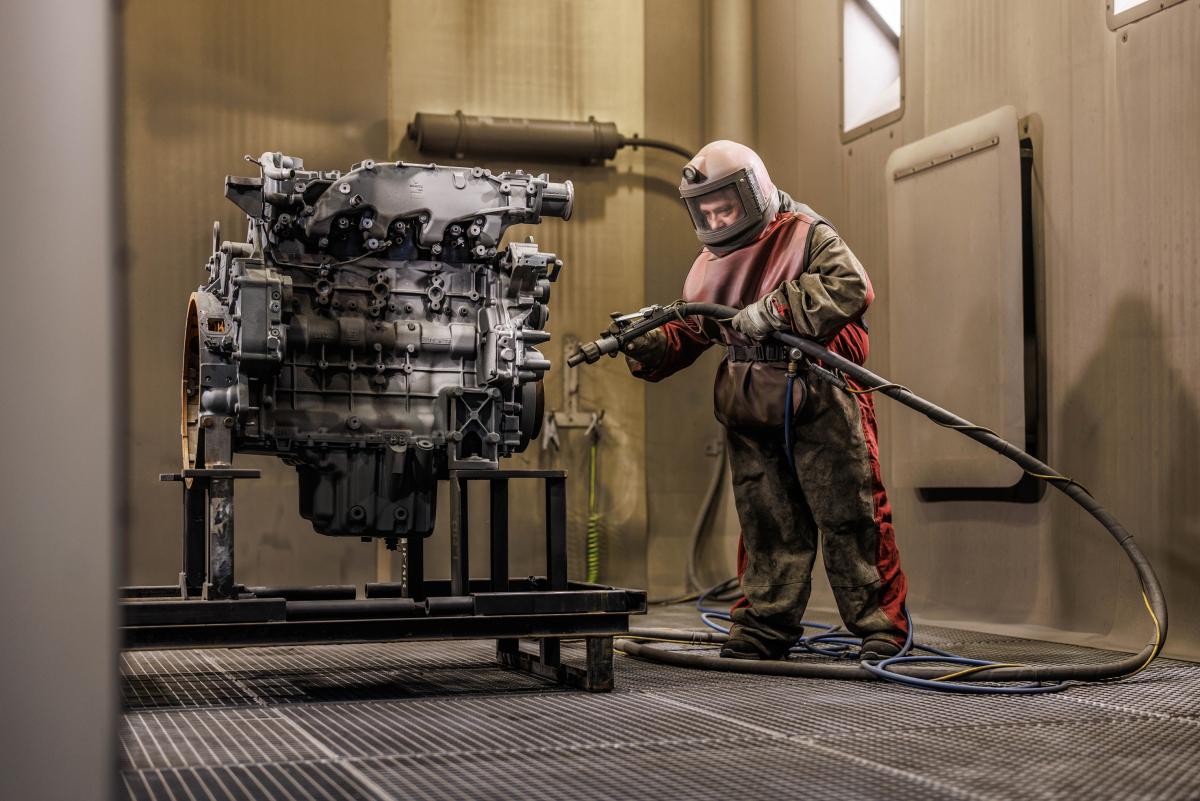

The reconditioning of engines, gearboxes and other components saves valuable raw materials – every year, 7500 components and numerous individual parts are reconditioned through the Liebherr Reman programme

The reconditioning of engines, gearboxes and other components saves valuable raw materials – every year, 7500 components and numerous individual parts are reconditioned through the Liebherr Reman programme

© Liebherr

The Reman programme gives engines, gearboxes and hydraulic pumps a second lease on life

Visitors can find out more about the Liebherr remanufacturing programme in the pavilion at the booth. Remanufacturing, or Reman for short, focuses on the reuse of existing structures of the product segment earthmoving and material handling. Combustion engines, hydraulic pumps, cylinders and motors, all types of gearboxes, as well as cable winches and electronic components, are dismantled, cleaned and inspected in detail. Depending on their condition and requirements, the individual parts are reworked and then reassembled into a complete component. There are three different reconditioning levels: Replacement with refurbished components, general overhaul and repair. The programme is growing within the Group worldwide and is already offered at 15 Liebherr sites today. Currently, 7500 components and numerous individual parts are reconditioned each year through the Reman programme.

The Group therefore makes an important contribution to conserving resources. As the original manufacturer, Liebherr can recondition used components so that they match the performance and reliability of new components. As an alternative to new parts, spare part costs are reduced by up to 50 %. By reconditioning combustion engines, for example, up to 78 % of raw materials can be saved. This is an important contribution to the circular economy, which also brings many advantages for customers.

Outdoor area: Booth N 224