Precise measurement of bulk material inventories using LiDAR

27.05.20223D LiDAR sensor technology, until now known primarily as the central technology for the environmental detection of self-driving cars, is also ideally suited for measuring the volume of mineral raw materials. Until now, their measurement was often inaccurate, associated with high effort and considerable costs, and was therefore rarely carried out.

LiDAR sensors enable measurement of bulk material inventories

LiDAR sensors enable measurement of bulk material inventories

© Blickfeld

With the help of 3D LiDAR, companies along the process chain from the extraction to the further processing of raw materials now have a way to know very precisely about their inventories at any time and to easily feed the data into their IT systems in digital form. This gives companies a much better basis for planning than before and enables them to make their processes more efficient by further digitizing their supply chain.

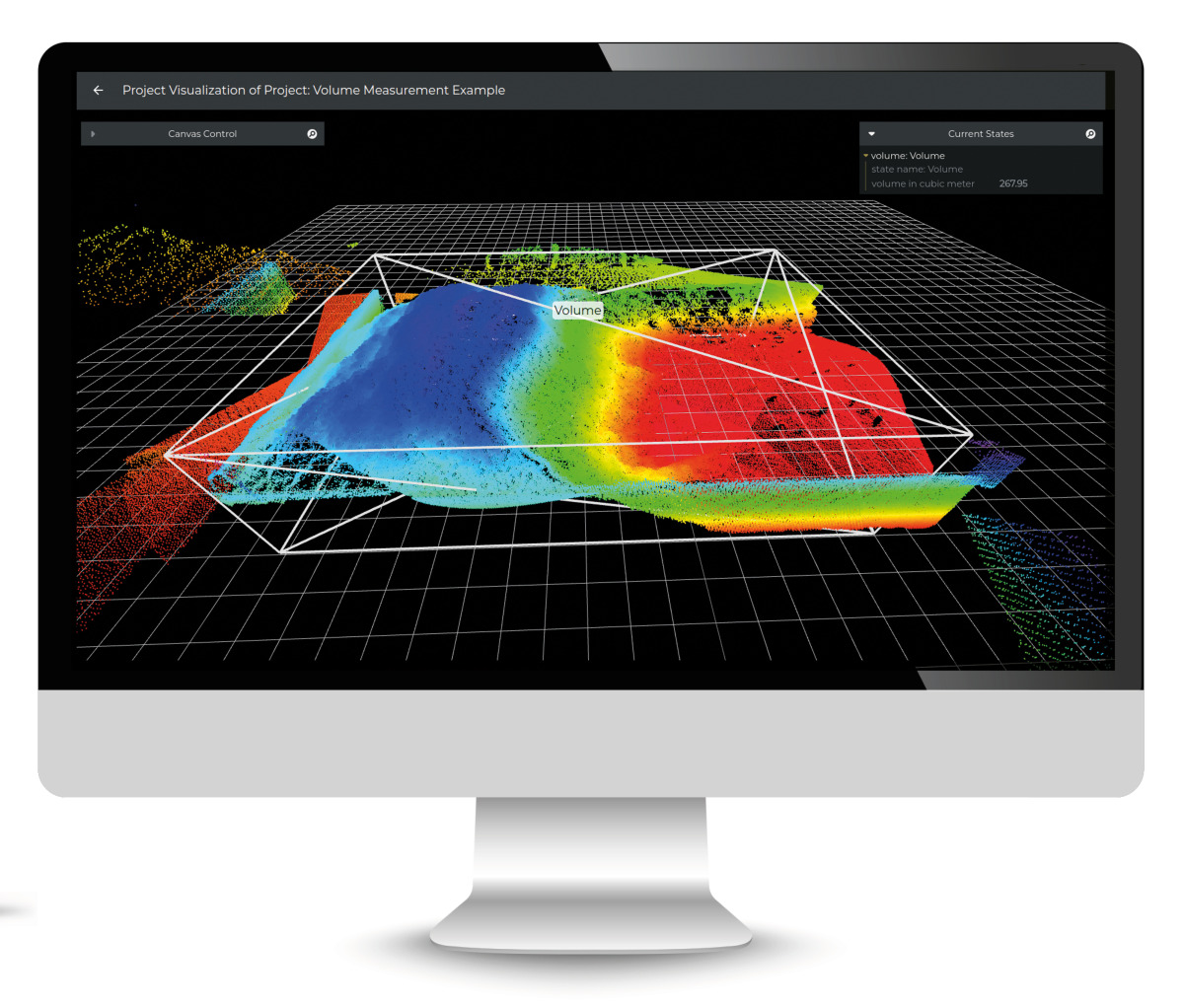

How does it work? LiDAR sensors emit hundreds of thousands of laser pulses per second and calculate the distance of objects, such as mineral raw materials, with centimeter precision from the time it takes for the reflected light to arrive back at the sensor. A fine-grained digital network is laid over the object, from which the volume and weight can be deduced with the aid of special software. The data is available in digital form and can be automatically fed into the IT systems, where it is always available to employees for their planning.

Sachtleben Technology uses Blickfeld LiDAR sensors to measure bulk material inventories, providing a precise overview of the actual amount of product in the warehouse, accurate to the minute.

Challenge: Inaccurate inventory calculation due to manual measurement methods

Previously, inventory has been measured extremely inaccurately or with very expensive measurement technology. As a result, many of Sachtleben Technology’s customers had no data of the actual amount of product stored in the warehouse prior to using LiDAR technology. Therefore, the goal is to accurately determine inventory levels to increase the productivity and efficiency of the companies’ supply chain management.

Solution: Volume measurement with LiDAR enables real-time inventory measurement

To capture material inventory in warehouses, Cube 1 LiDAR sensors are attached to the ceiling using adapter plates with network and power connections. The 3D data generated by the LiDAR sensors provides information on the height, width, and depth of the bulk piles accurate to the centimeter. In a next step, a software solution calculates the material’s mass on the basis of this data.

The solution also offers the advantage of precise and real-time registration of the point clouds for the material piles. Each sensor outputs the acquired data as a point cloud, containing the x, y, and z distance coordinates. The fusion of multiple point clouds from sensors placed in a warehouse allows the entire inventory to be recorded at once.

"We were looking for a laser-based 3D sensor that would provide continuous and detailed data for volume measurement of bulk materials in a warehouse. With the Blickfeld Cube 1, we have found asmall, lightweight, robust, and cost-effectiveLiDAR that precisely meets our requirements.", says Quirin Kraus, Co-Founder & COO, Sachtleben Technology.

Outlook: More industries can benefit from volume measurement with LiDAR

In addition to installing LiDARs in warehouses to measure inventory, there are a few other application areas that may benefit from the use of this particular technology, like port facilities or gravel plants. Furthermore, a mobile version of the application could be interesting for construction sites, for example, to measure excavation.