Resand launched an innovative, electrically driven sand reclaimer

10.06.2024Resand Ltd, which specialises in the regeneration and recycling of foundry sand, is the first company to launch an electric sand reclaimer on the European market. The reclaimer unit is a modular system that is quick and customer-friendly for the foundry to install and commission, with a delivery time of only 4 to 5 months.

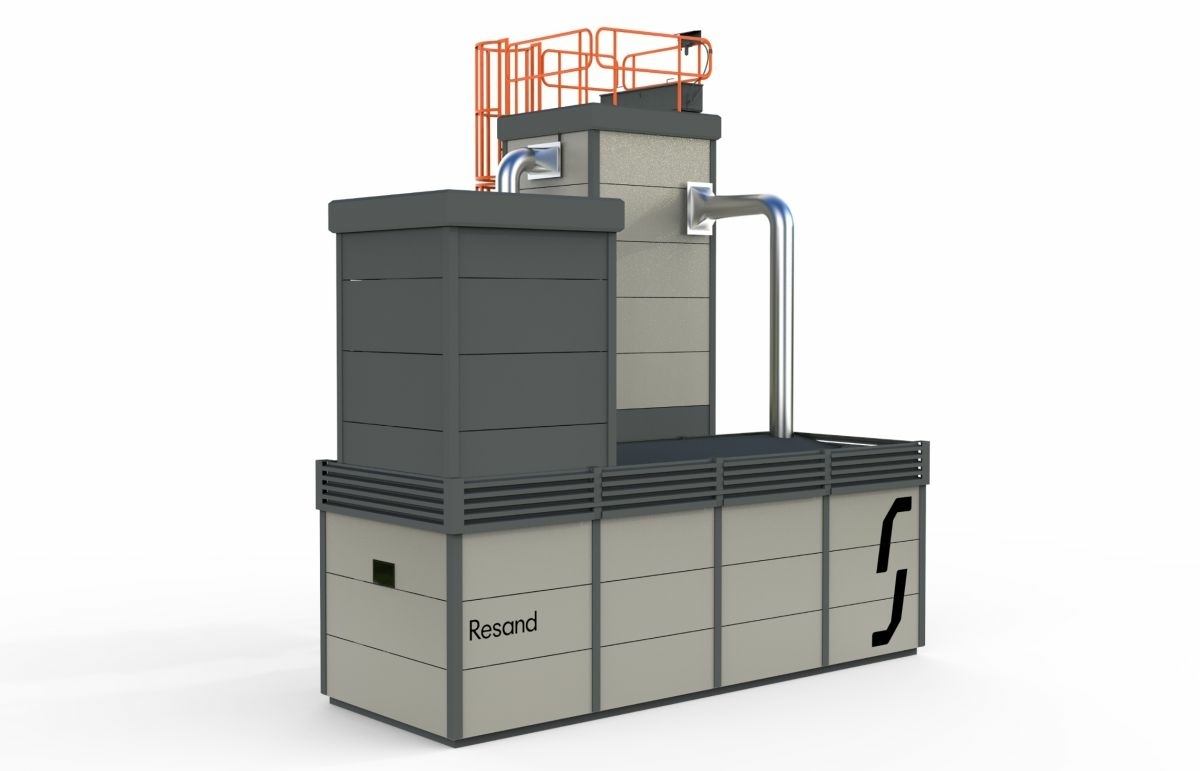

Resand electric sand reclaimer

Resand electric sand reclaimer

© Resand

With the electrically powered reclaimer, CO2 emissions from the use of new sand and associated transportation can be reduced by up to 70 %. When using renewable energy, the reclaimer's direct greenhouse gas emissions, i.e. Scope 1 emissions, remain low.

Resand's electric sand reclaimer is specially designed for medium-sized foundries, and it has a production capacity of 1000 kg of recovered sand per hour. With an electrically heated drive, the sand reclaimer is very easy to connect to the foundry’s mains, which means that clean sand is always available at the foundry.

The first SAAS (Sand As A Service) agreement for the new electric reclaimer was signed in April with a Finnish foundry. With the agreement, sand regeneration will take place at the customer foundry's production facilities. After regeneration, the sand can be used again and again in foundry processes, effectively reducing the need for virgin sand.

"Our business has always been guided by innovation and understanding of customer needs. I am very proud of our first service agreement for an electric sand reclaimer. I see a promising future for the electric reclaimer, as the foundry industry both in Finland and elsewhere in Europe has been hoping for an electrically powered modular sand reclaimer solution," says Kalle Härkki, CEO of Resand Oy.