Superior bringing big iron and bigger ideas to CONEXPO-CON/AGG 2026

27.11.2025Superior Industries, Inc., a US-based manufacturer and global supplier of bulk material processing and handling systems, is returning to CONEXPO-CON/AGG with its largest outdoor footprint yet. The company will showcase new equipment, system-wide solutions, and hands-on experiences from booth SV2374 in the Silver Lot, where more than 60 Superior team members will welcome visitors from across the industry.

“When you step into our booth, we want you to get a clear picture of what Superior Industries stands for,” says Jason Adams, the manufacturer’s president. “Yes, we’re bringing a lot of iron, but more importantly, we’re bringing a winning team that loves this industry, is fun to work with, and genuinely wants to help our customers succeed.”

This year’s booth layout is designed to feel open, approachable, and easy to navigate, giving visitors a complete look at how Superior’s growing portfolio of crushing, screening, washing, and conveying products connect across real-world applications.

Here are some of the new products making their debut in Las Vegas:

Independence™ High Frequency Screen Plant

Independence™ High Frequency Screen Plant

© Superior Industries

New: Independence™ High Frequency Screen Plant

Built to make spec from challenging feed, this new plant pairs a multi-slope 6 × 20 two-deck design with a vibrating feed box that spreads material evenly for stronger stratification and maximum open area utilization. Outboard motors simplify inspection and maintenance, VFD control allows individual tuning for each deck, and a fully-enclosed body reduces dust. An automated clean out cycle helps move sticky material, resulting in up to 20 % more capacity in the same footprint.

Next-Generation Cemco® Vertical Shaft Impactor

Next-Generation Cemco® Vertical Shaft Impactor

© Superior Industries

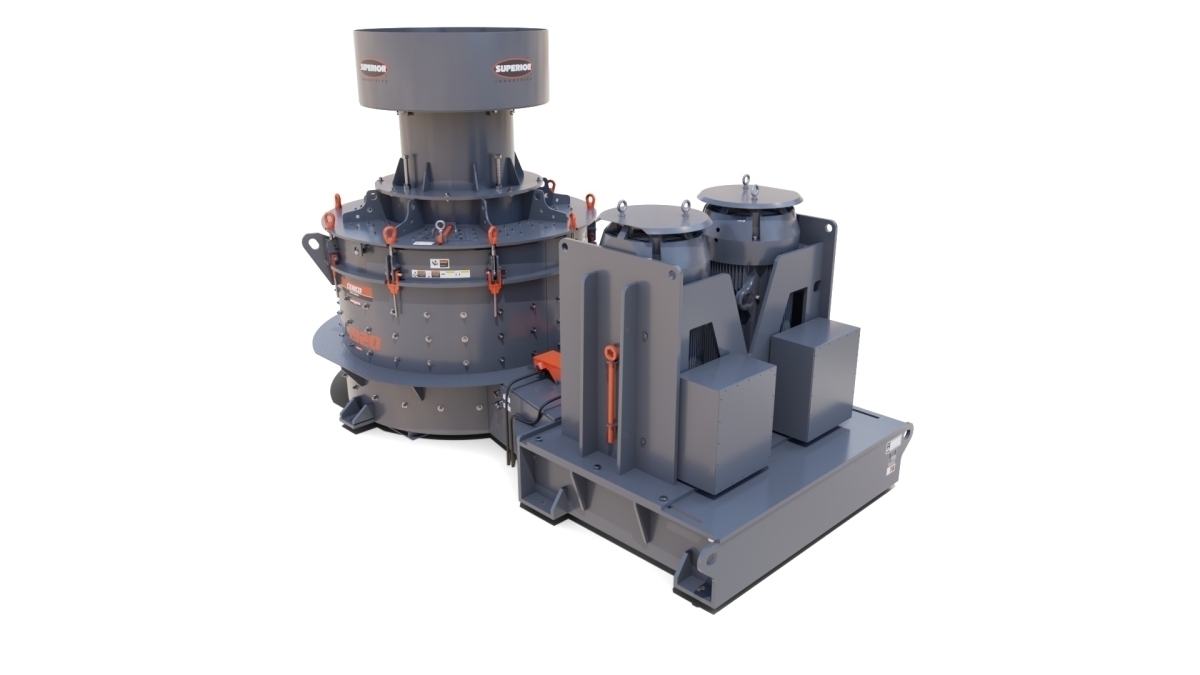

New: Next-Generation Cemco® Vertical Shaft Impactor

Merging the strengths of the legacy Cemco platform with features from Superior’s Valor® VSI, this redesigned crusher delivers optimized rock on rock performance. New rotor and chamber geometry boosts efficiency, and a rotating anvil ring extends component life. The platform maintains parts commonality across models and offers multiple chamber and rotor options. A C1920 with a v-twin drive will be displayed in the booth.

600 HP Crushing Performance on a P500 Frame

600 HP Crushing Performance on a P500 Frame

© Superior Industries

New: 600 HP Crushing Performance on a P500 Frame

A factory-approved power upgrade now rates the P500 Patriot® Cone for 600 HP, giving portable operators more output without oversize permits or heavy haul requirements. The show unit will be mounted on a rear feed, rear discharge portable chassis equipped with hydraulic leveling legs and a large observation platform.

Self-Contained Portable Radial Stacker

Self-Contained Portable Radial Stacker

© Superior Industries

New: Self-Contained Portable Radial Stacker

Superior’s redesigned self-contained stacker delivers dependable performance at a competitive price point. Updates to the truss depth, power supply, and load zone hopper improve efficiency while the onboard engine powers up to 500 t/h. A steeper angle creates larger stockpiles in less space. Visitors will see a 36" × 80' model with hydraulic controls for the hopper wings, undercarriage, and folding head section.

Conveyor Transfer Zone Skirting Solutions

Conveyor Transfer Zone Skirting Solutions

© Superior Industries

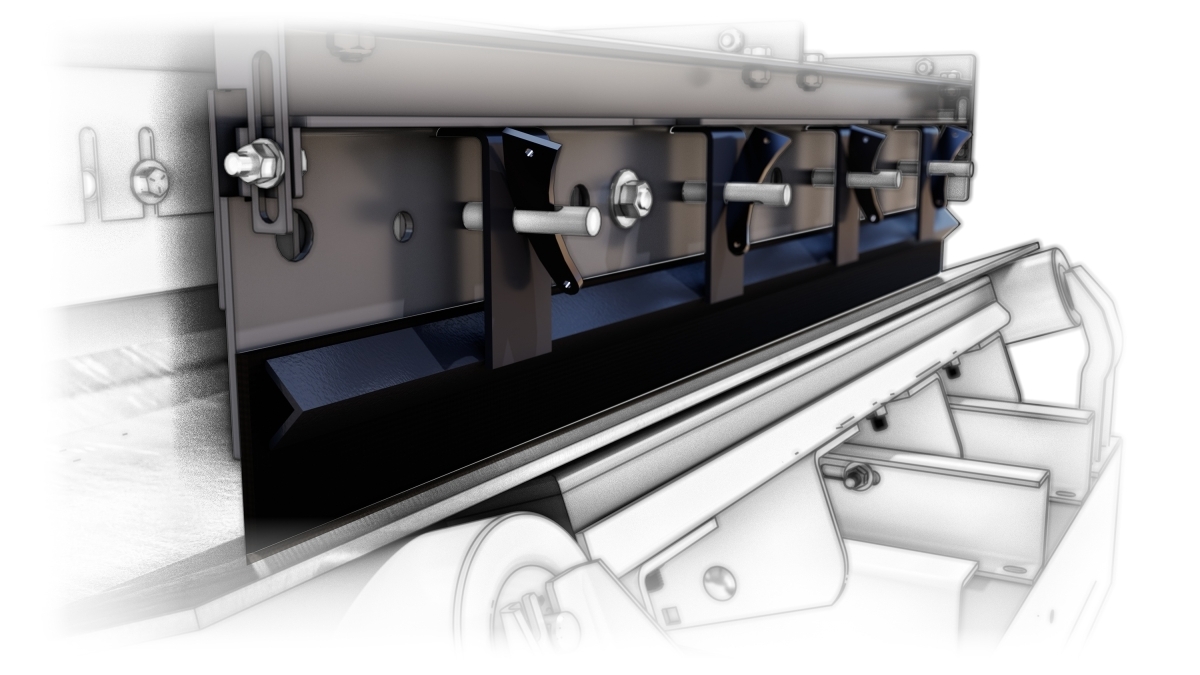

New: Conveyor Transfer Zone Skirting Solutions

Superior is introducing an updated set of skirting solutions designed for cleaner, tighter control across load and transfer zones. Newly designed Adjustable Skirtboards arrive in preassembled sections with trim to fit mounting legs to match individual conveyor designs. Paired with them, RockGuard™ Skirting Liners add dust sealing through steel backed rubber or urethane options in a range of lengths, heights, and thicknesses. Producers can choose flat or beveled edges to manage everything from heavy impact to high speed fines.

These new releases will stand alongside a TeleStacker® Conveyor, RazerTail® Truck Unloader, Liberty® Jaw Crusher, Endeavor® Cone on a Fusion` Modular Platform, Dakota® Cone, Aggredry® Dewatering Screw, Guardian® Horizontal Screen, and nearly three dozen other conveyor components covering idlers, pulleys, belt scrapers, and problem-solving accessories.

Inside the Construction Management Tunnel

Superior’s Construction Management division will anchor a section of the booth that guides visitors through an interactive map of completed turnkey projects. Each site reveals a look at services delivered, products installed, and results achieved, supported by video, photography, and other project visuals. Members of the team will be available for conversations about design, planning, installation, commissioning, and long term optimization. With a growing demand for integrated site development, this team continues to expand its output and capabilities.

An interactive booth challenge with prizes

A planned booth challenge will encourage visitors to get moving through the entire space in a fun, interactive way. Guests can scan QR codes placed throughout the booth to unlock quick tasks. Each completed challenge earns points toward prizes and encourages attendees to explore more of the booth. It’s a simple, engaging way for visitors to experience the depth of Superior’s full product portfolio across crushing, screening, washing, conveying, and components.