Terex charters vessel to ship 30 machines from UK to Australia

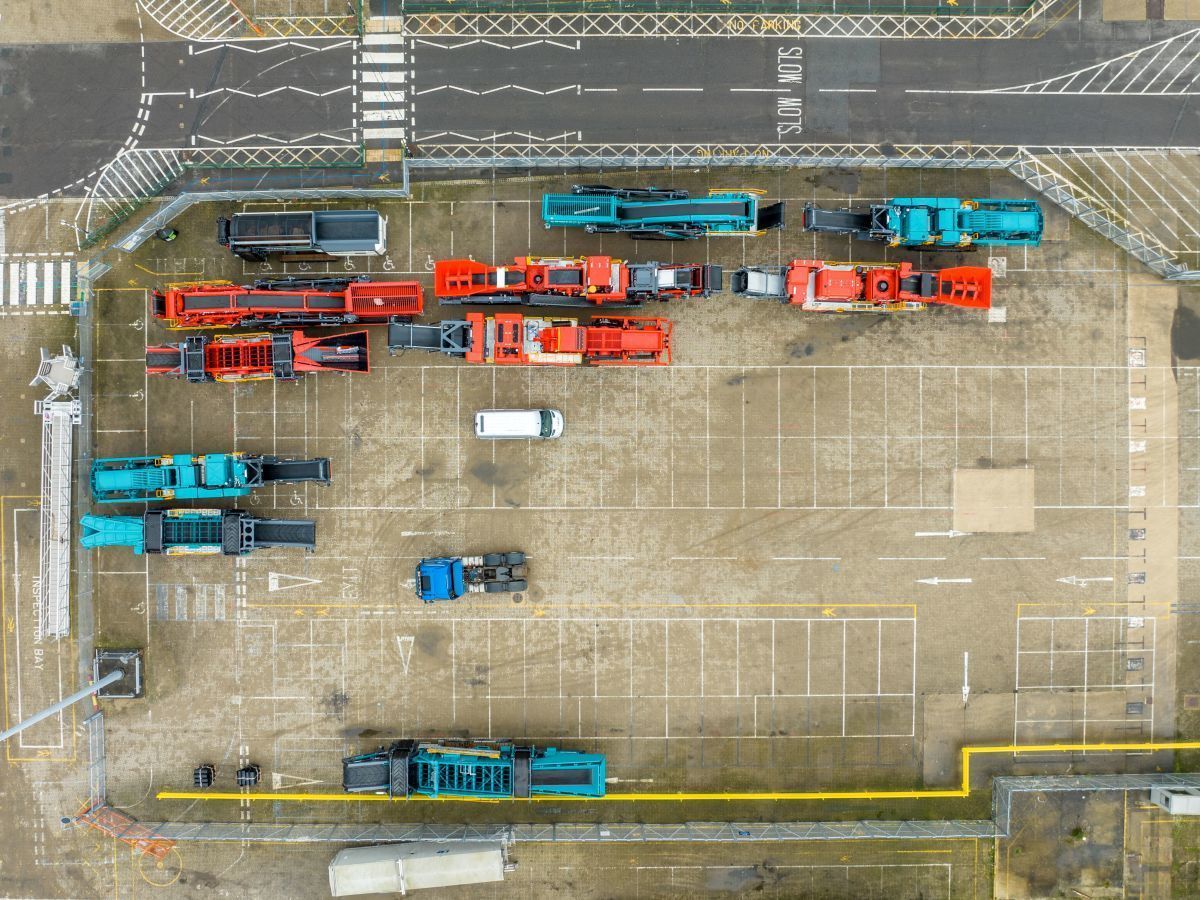

20.02.2023Terex in cooperation with DHL Global Forwarding’s Industrial Projects division has successfully chartered a vessel to convey a consignment of 30 Powerscreen®, Finlay® and Terex Ecotec machines from Southampton/UK to Brisbane/Australia. In what has been a mammoth, first-of-its-kind practice for Terex, the successful charter was to ensure customers get their machines in these times of logistical and supply chain delays.

© Terex

© Terex

Claire Hamilton, Category Director – Metal Fabrications & Logistics, Terex Supply Management and Transport, said: “Towards the end of last year, our RORO (roll-on/roll-off) capacity to Australia was suspended due to port congestion, backlog due to COVID, and increased global demand. Vessels were overbooked and backlog was not reducing. While we were provided with an allocation of slots, this did not meet the demand for our products. We decided to research alternative options for getting our equipment to our Australian customers, which was a huge undertaking. Our equipment varies in size and weight and not only is lifting them on, and off vessels difficult, safety of doing so is always our top priority. After exploring various options, we found a solution that enabled our machines to be tracked and secured onto a platform, which would be lifted by cranes and lowered into the hull of the ship.”

© Terex

© Terex

Prior to loading, the Terex Sourcing and Supply team worked with various stakeholders –including safety, engineering, logistics, operations teams within Terex, as well as external transport and shipping providers – with biweekly meetings to plan every detail. Specific engineering information was provided for each machine, and dates agreed among all parties for getting machines to port. In total, 30 Terex machines weighing 1,092 mtons / 5,012 m³ were delivered to the Port of Southampton.

© Terex

© Terex

Even when at the port, support was provided to transfer the machines from storage to dockside, providing solutions as problems occurred, with Terex service engineers checking machines prior to loading and supporting stevedores at the dockside and on the vessel. Loading to the vessel was performed by tandem lift operation of the ship’s cranes and lifting platform. Embarkation and disembarkation to and from the ramp was undertaken using ramps on the quayside and in the ship’s hold. In total, it took eight days for all 30 machines to be safely loaded to the vessel.

© Terex

© Terex

Claire summarises, “From the planning stages right through to the enormous operation of loading our equipment onto the vessel, all stakeholders worked proactively to ensure that our 30 machines were loaded safely to the vessel with no incidents or accidents. It was a huge undertaking – constant collaboration between internal and external parties, working as a team, was a key contributor to success.”

© Terex

© Terex

The machines are currently enroute and expected to arrive in Australia in early March 2023.