Properties

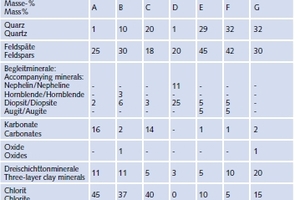

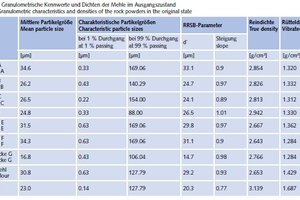

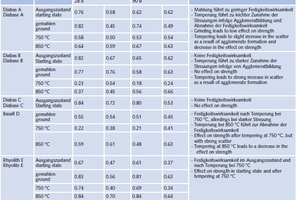

Rock powder as aggregate for hydraulic binders

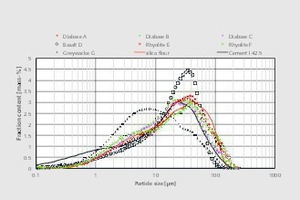

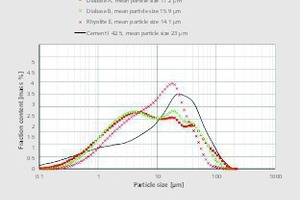

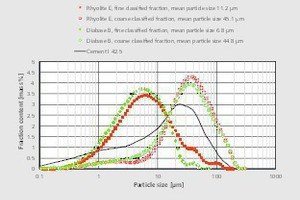

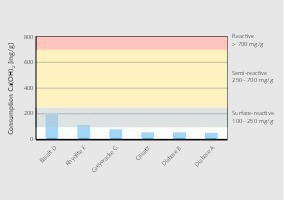

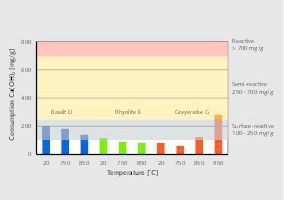

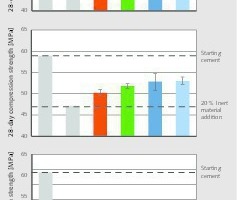

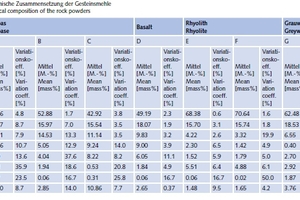

Summary: In the extraction and production of high-grade aggregates, the formation of finely dispersed particles is unavoidable. Up until now, these rock powder were only partly or not utilized at all. A research project sponsered by Germany’s Federal Ministry for Economic Affairs and Energy and supported by the industry was initiated to evaluate possibilities for using these materials in cements and concretes to utilize their dispersity and/or chemical properties. First, the influence of the particle size distribution on the packing density was investigated and the effects of a particle size distribution modified by grinding and classification were evaluated. The second focus was on reactivity in an alkaline milieu, certain specimens undergoing additional thermal treatment.

1 Current knowledge

The effect of finely dispersed waste and by-products in cements and concretes has been the subject of a large number of studies. In the case of the waste products used as cement substitute, so far the focus has been on “traditional” industrial by-products such as slag sand, coal fly-ash and microsilica [1-4]. In recent years, the studies have been widened to cover kaolins or clays [5-8]. In the case of these materials, the reactive potentials are first generated by means of thermal treatment so that the materials can then be used as a cement component [9-20]. Other studies...