Solid and compact

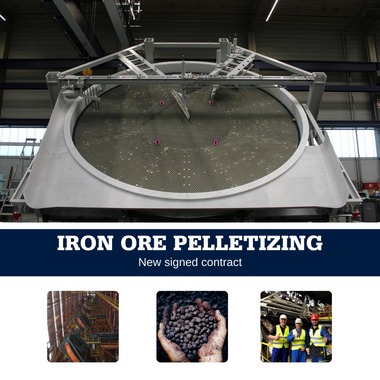

Improving the quality of raw and waste materials with the application of pelletizing processesSummary

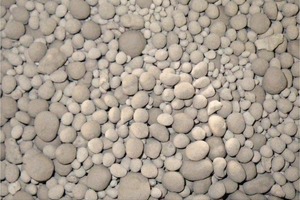

Agglomerates are the hidden companions of our day-to-day life. Everyday we use a multitude of products from different industries all produced with the help of agglomeration technology. With reference to examples from different sectors, the versatility of pelletizing discs for agglomeration is illustrated. Prior to the application of pelletizing discs for agglomeration, it is always necessary to assess the basic pelletizability of the different materials as well as to obtain data for the machine and process design on the basis of empirical testing on laboratory or pilot-plant scale to enable reliable parameterization of the pelletizing process.

1 Introduction

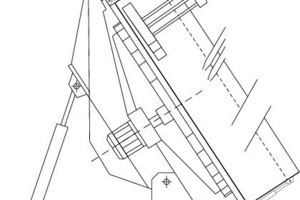

With its special material bed kinetics, a pelletizing disc combines agglomerating, comminuting and classifying mechanisms in one process chamber. Owing to these parallel mechanisms and the high number of machine, process and material-specific influencing factors, it is not possible to dispense with preliminary tests in the planning of agglomeration systems, even if certain empirical correlations are known. Objective of these preliminary tests is the determination of the settings for the pelletizing disc, the appropriate material conditioning and the dimensioning as a function of...