ContiTech involved in the first subsea mineral resource project

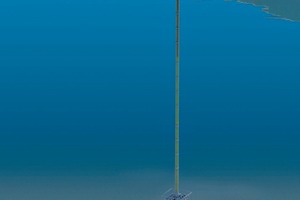

ContiTech has achieved another milestone: Its Fluid Technology Oil & Marine segment has been commissioned by the Canadian company Nautilus Minerals Inc. to take part in the world’s first deep-sea mineral resource project. The undertaking will see natural resources extracted from sulphide-rich deposits found on the ocean floor (Fig.). Nautilus’s Solwara 1 extraction project in the Bismarck Sea near Papua New Guinea will be equipped with high-tech hoses specially developed by ContiTech to operate successfully in the extreme conditions found at depths of more than 1600 m.

In collaboration with Nautilus’s contracted engineering partner Technip, ContiTech has engineered hoses that will manipulate and take up the often sharp-edged stones dredged up from the seabed by the remotely operated Seafloor Production Tools. In addition, ContiTech has developed a 155 m riser transfer pipe that will connect to the long, rigid riser pipe to bring slurry from the sea floor up to the surface. A series of buoyancy units have also been created specially for this ambitious project. These will hold the hoses produced by Oil & Marine in an S-shaped arrangement under water and prevent them from sinking to the ocean floor as they bring natural resources up to the Production Support Vessel. Together, these elements will play a key part in the success of this project.

Explaining the choice of ContiTech and Technip as development partners, Nautilus Minerals Project Manager, Mike Howitt said: “For this pioneering project, we wanted the support of specialists with significant expertise in offshore mineral extraction.” The project is currently on track to commence production in late 2013. It will initially produce 1.2 million t of material, with production ramping up 1.8 million t in due course. “This project is unique. We tested the durability of our hose at our Hungarian plant in Szeged under the toughest possible conditions for more than four months. During that time, we were able to prove that our high-performance hoses withstand not only outside pressures of up to 35 bars but also the environmental conditions at the site. Particularly important is the fact that we have managed to produce a lining for the hose that is extremely resistant to abrasion and very slow to wear down,” says Peter Neale, President of ContiTech Beattie Corp. in Houston outlining the key requirements of the high-tech products. With only limited storage capacity available on the Production Support Vessel, the hoses had to be designed with easy handling and storage in mind, which presented a further consideration in terms of the hose design.

Massive sulphide deposits in the Bismarck Sea, on the edge of the Pacific Ocean off the coast of Papua New Guinea, were first discovered in 1996. Investments in the Solwara 1 project have totalled over 400 million US$. Nautilus Materials has obtained rights to extract the minerals for 25 years and has appropriate approval from environmental authorities.