Automation based on permanent quality control in the material flow

As a universal technology for reliable particle size analysis, the GeoScanner cannot be beaten by any other process at the moment. With the help of a tried and tested and now mature method, the acoustic signals generated by the individual particles as they impact a sensor are “translated” into application-specific data and used as a key parameter for the automation of complete processes.

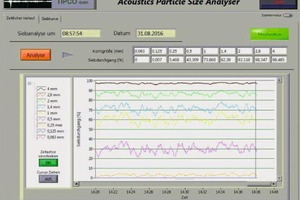

Installed on belt conveyors, in pneumatic transport systems, but also in the discharge flow of bulk solids in freefall, the system scans the particle size distributions online at one-second intervals. The process for just-in-time process monitoring, plant monitoring and quality control is a state-of-the-art system solution that can combine dedicated hardware components (sensors) with a specially developed analysis software and control features. By developing customized solutions from the basic universal syste, for different industry partners – including well-known raw and building materials producers, suppliers of industrial minerals, but also companies in the automotive industry, Tipco has been able to further refine the GeoScanner technology in the course of the past eight years. So, the process is not only suitable for the measurement of any type of particles, grains and granulates, it also covers an incredibly wide measurement range, which spans from around 60 μm to decimetre sizes.

From individual data for process optimization

With high-frequency measurement intervals of less than a second, the GeoScanner decodes all mass flows independent of the density of the material and its chemical composition. The universal process can be integrated in all industrial processes. Following their unique calibration, the robust, reliable and wear-resistant sensors used permanently deliver the required information. This is directly visualized, stored and, if required, remotely transmitted. The biggest benefit is brought ultimately by the integrated signal output for the plant control. Thanks to this, in the feedback, processes can be automatically optimized so that the product quality always attains the highest possible level.

With the efforts to maximize efficiency, online monitoring of particle size distribution is a field of business with a big future and an elegant path to automatic process optimization for implementation of Industry 4.0 in the bulk solids processing segment. The ongoing, unmanned analysis based on acoustic parameters is moreover a successful innovation in the industrial processing world. The forerunner to this system was a team of researcher with the courage for lateral thinking. From the first innovative idea, through many trials to the precision process now available as a product of Tipco GmbH, it took a total of fifteen years.

In the meantime, the GeoScanner has arrived in the field, gaining ever wider application, after all which operator doesn’t want a running process to automatically regulate itself back to the optimum operating point as soon as a grain size range or mass flow diverges from the defined target. That functions so perfectly with the GeoScanner because the particle size distribution is a sort of multi-indicator and therefore a reliable measure for innumerable process properties. Bulk and packing density, porosity, surface condition, solubility, water absorption, affinity to binders, consumption of additives and dispersion properties through to smell and taste depend on the particle size. With permanent target/actual comparisons of the grain sizes at certain points in the overall process, the quality of individual processes can be determined and, if necessary, corrected instantly. At the same time, in this way all machines can be monitored. If malfunctions or damage occur, these can be instantly identified from diverging values in the material flow. Based on the feedback from the grain to the process, reliable machine and plant control is guaranteed. This leads not only to improved product quality, but also an increase in plant and energy efficiency. Even downstream processes profit from online particle size analysis as the dosing – e.g. of binders – also depends ultimately on the particle size.

The particle size curves generated every second with the online particle size analysis also demonstrate their high useful value in other areas of application. GeoScanners used, for example, in laboratories perform excellently. Even in tunnel construction, in investigations of building land and for exploration work in mining, bespoke versions of the GeoScanner impress. But despite everything that has been achieved so far, this does not have to mark the end of the spectrum of applications. New project enquiries can result in the potential of the GeoScanner growing to be a lot bigger than currently assumed.

//www.tipcogmbh.com" target="_blank" >www.tipcogmbh.com:www.tipcogmbh.com