High resolution on-line particle size analysis on highly concentrated ore slurries

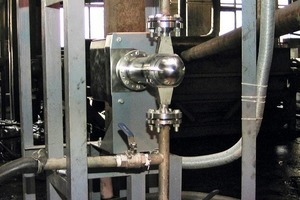

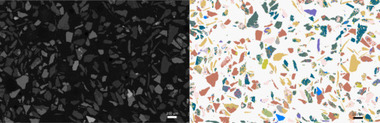

The particle size distribution of ground minerals is of decisive importance for downstream processes like flotation, separation, drying or others. In order to optimize the process efficiency on one hand and the final product quality on the other hand an early control of the grinding or classification stage is essential. The ultrasound based particle size analyser OPUS is capable of performing on-line particle size distribution (PSD) and solid content measurement of mineral slurries such as iron ore, copper ore, fluorspar, or quartz sand and alumina directly in heavy and rough process environment. The instrument provides a PSD of 31 size classes and can be applied for particles from nanometer range up to several millimetres. Arbitrary interpolations in between the 31 measured points are available. Typical residue values show an excellent agreement to off-line particle size analysis methods such as e.g. sieve analyses or laser diffraction. OPUS is designed as rugged in-line probe made from stainless steel. The applied technique is independent of product flow dynamics, contamination, optical properties, vibrations, pressures or changes in solid concentrations. The instrument provides all data on the system’s PC or on the process control system by a variety of interfaces.

1. Introduction

For the down stream processing of ore slurries the particle size distribution behind the milling and cyclone stage is of decisive importance. Slurries with excessively coarse particle sizes hardly can be pulped mechanically or require extensive and expensive solvents for chemical pulping. Usually, the subsequent flotation step requires a specific particle size distribution for smooth operation, too. In order to avoid over size particles, an extended grinding time or lower feed rates are applied which require higher energy consumption and smaller throughputs. On the other hand,...