BEUMER Group

The BEUMER fillpac® R filling machine fills bulk material from the building materials industry and other industrial pulverized goods into different bag sizes and types like valve bottom and flat valve bags in an efficient and gentle way and with the required throughput. The structure of the materials can be very fine to very coarse. The BEUMER bag placer® and the ream magazine supply the rotary filling machine with empty bags to ensure the high throughput. The highly efficient form fill seal system BEUMER fillpac® FFS is used in the chemical and petrochemical industries. It forms bags from a prefabricated tubular PE film and fills them with the product. The customers can select the optimal machine performance class from this product family depending on their requirements.

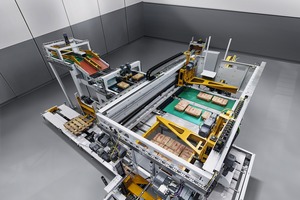

BEUMER Group offers different palletising solutions, depending on the packaged items. The BEUMER paletpac® is suited best for bulk material. It is incorporated into high-performance packaging lines to process even sensitive and valuable products as well as products with special flow characteristics in a gentle and efficient manner. Depending on the product requirements, these palletisers can be equipped with a clamp-type or twin-belt turning device which turns the filled bags quickly into the required position for stacking, ensuring their dimensional stability without any deformations.

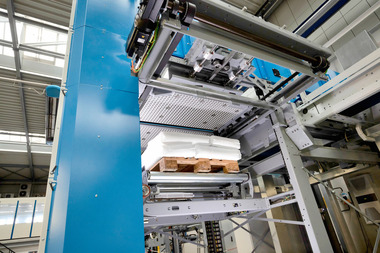

Packaged items stacked accurately on pallets can then be transported successfully to the downstream packaging system – for example, the BEUMER stretch hood®. It covers the palletised goods with a highly stretchable film. During transshipment and outside storage, the merchandise is protected reliably against environmental influences such as sunlight, dirt and humidity.

Hall 1 / 627