Calm crushing in London’s city centre

Quiet impact crusher

In addition to emissions, the City of London also regulates noise. No problem for RM crushers. “Whenever I visit a construction site where a RM crusher is working I am again and again surprised how low the noise level of the machine is compared to other crushers,” says Paul Donnelly, Director of Red Knight 6. The secret lies in the noise-reducing design, which makes the RM 70GO! 2.0 the perfect crusher unit for operating in noise-sensitive areas. Over the years, the RM engineers have developed and optimised various noise reducing components such as the engine cladding, mounting and ventilation louvres. As confirmed by the results of the standardised measuring procedure: the mean noise pressure level (Lp) at a distance of 10 m is 80.6 db(A) and at a distance of 100 m it is 60.6 db(A), making the RM 70GO! 2.0 a very quiete crusher.

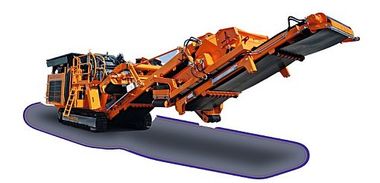

Powerful, mobile, intuitive

It‘s not only about making low emissions count, the output needs to be great as well. Again this is no problem for the RM impact crusher: with an average throughput of 125 t/h the job at Haverstock Hill Road was finished within five days. The high mobility of this outstanding compact crusher was impressive in the narrow job site. With a width of only 2200 mm the RM 70GO! 2.0 was able to drive through the narrow gateway into the site between two multi-storey buildings and turn around. “The RM crushers are very intuitive to operate. That is one of the reasons why we love the RM impact crushers and makes them perfect for hiring. With the remote control the RM 70GO! 2.0 is easily moved from one location to the next. It also only requires one person to operate the excavator and control the crusher, which saves time and money. You can even crush and drive at the same time. It is all these ‘little‘ things that make the big difference with RUBBLE MASTER,” says Paul Donnelly.

//www.rubblemaster.com" target="_blank" >www.rubblemaster.com:www.rubblemaster.com