Condition monitoring as key components of Industry 4.0

“Many drive system manufacturers came to HANNOVER MESSE with new CMS systems and system refinements. That is because continuous condition monitoring, itself a form of factory intelligence, is an integral component of the Industry 4.0 vision, as reflected in the HANNOVER MESSE motto of ‘Integrated Industry’,” remarked Marc Siemering, Senior Vice President responsible for HANNOVER MESSE at Deutsche Messe.

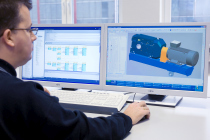

This view is shared by Hartmut Rauen, the Deputy CEO of the German Engineering Federation (VDMA) and the VDMA management board member in charge of power transmission and fluid power. “Power transmission and fluid power technology are fast becoming key components of Industry 4.0 (Fig. 2),” he said. “Intelligent actuator units and actuator CPS modules for instance are currently being used to capture, understand and interpret actuator motion and function data and wear parameters. To that extent, condition monitoring systems are already being put to work to create viable business models.”

Robert Schullan, a member of the Management Board of the Schaeffler group and in charge of its Industrial Division, is keenly aware of the importance of condition monitoring systems: “Smart actuators and drive components with built-in sensors are key to integrating machines and equipment and controlling autonomous systems in our customers’ value chains,” he said. For this reason Schaeffler regarded condition monitoring systems as one of the central themes at MDA, he continued. The company’s innovations on show at MDA included a new antifriction-bearing torque measurement module that provides the basis for autonomous machine state monitoring. The torque data are analyzed using Schaeffler’s SmartCheck system, which can also be used in compressors, vibrating screens, vacuum pumps and a range of other applications. The SmartCheck measures parameters like wear, misalignment, out-of-balance states and ambient as well as motor-casing temperature, thus providing self-monitoring capabilities for machines. As two major trends in this area of drive technology, Schaeffer sees the correlation of substantially bigger volumes of data from multiple sources and the convergence of process control with system monitoring.

So, what specific innovations awaited visitors at this year’s MDA show? Well, for one thing, Parker Hannifin presented the latest addition to its range of CMS system solutions. This involved a series of new sensors that can measure a variety of parameters, such as the viscosity, density and dielectric properties of hydraulic media, and which eliminate time-consuming calibration processes (Fig. 3). The company also showcased a new measuring technology that simultaneously counts particles and measures relative humidity. In terms of general industry trends, Parker Hannifin points to a move towards integrated CMS solutions. “Customers now want total system health management solutions that capture and rapidly analyze all the relevant data,” explained Parker Hannifin’s Sales Manager Hydraulic & Engine Filtration, Stefan Nilgen.

Condition monitoring was also a key theme at the Festo stand at MDA, where the company showcased its CPX valve terminal – an automation module that connects pneumatic and electrical systems. The terminal has a modular design with integrated condition monitoring functionality, diagnostics, and electrical and pneumatic safety functions. The Festo stand once again featured a fascinating new bionics study that provides a fresh perspective on a range of topics, including condition monitoring and diagnostics.

Fluid-power specialist Argo-Hytos used MDA to showcase a range of hardware-based CMS solutions for hydraulic systems. It also presented its “CMS Systems & Services” package – a suite of turnkey measurement solutions that includes installation, calibration and monitoring services. Christian Kienzle, CEO of the Argo-Hytos Group: “The data captured by condition monitoring systems provide the basis for plant integration and optimization in the sense of Industry 4.0. New digital integration and information processing solutions are opening the way for the optimization of ever more complex processes and systems. To harness the full potential of CM solutions, we are increasingly using intelligent CM components, which we tailor to our customer’s individual applications.”

Bachmann Monitoring came to MDA to present a CMS solution for end-to-end wind turbine drivetrain monitoring. According to Bachmann, one of the key technology trends in the wind energy sector is the development of integrated solutions that can monitor entire turbines, from rotor blade to tower foundation. Prüftechnik AG is another MDA exhibitor whose showcase centered around wind turbine technology. The company presented Vibguard XP, a new version of its proven Vibguard online condition monitoring system that was specifically developed for the wind energy industry. Vibguard XP captures and analyzes signals on up to 20 channels simultaneously. It can pick up irregular vibrations in the drivetrain and tower and can even detect the formation of ice on the rotor blades.

This brief overview highlights the central role of condition monitoring in “Integrated Industry.” CMS and how it fits into the overall control and process landscape was no doubt the subject of numerous discussions at the MDA stands and indeed the MDA Forum.

//www.hannovermesse.de" target="_blank" >www.hannovermesse.de:www.hannovermesse.de