Customers helped to improve Demarec two-cylinder concrete crushers

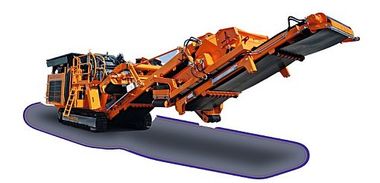

In 2018, Demarec introduced its new DCC series, widening its range with two-cylinder crushers for excavators up to 80 tonnes. One of the first crushers of this type, the DCC-75, premiered at Johann Ettengruber GmbH. It was delivered in variant A with a large jaw opening and high crushing force. A crusher that would make demolition more efficient and faster, that was Ettengruber‘s goal. Ettengruber has made a name for itself in challenging building and installation demolition projects. With a short blade and large crushing teeth area, the DCC-75 was apparently optimally equipped for this work. Kiesel fixed it to their Hitachi ZX670, adapted the pressure and power, and away they went with it.

Compared to other crushers, the new DCC-75 features 25 % more force on average, thanks to the high torque of the jaws and an enomous closing force of 200 tonnes. Moreover, valves and cylinders have been designed to guarantee fast oil flow and therefore fast cycle times. “A big advantage is demonstrated primarily in work with a long-front excavator,”explains Enis Coskun. When the driver is nibbling at concrete at a height of 30 m, the two-cylinder crusher is used synchronously for gripping. As a result, there is only little torsion movement at the arm und boom, with quiet running of the crusher.

Very quickly Ettengruber realized: a long blade would be even better for its work. “Longer blades would have more to set against the steel,” says Ettengruber. That was important information that Coskun immediately picked up on. In a joint visit with the design manager Ruud de Gier from Demarec to the Ettengruber construction site, a solution for the ideal bite was found on site: a long blade with exchangeable crusher teeth. Born was the C variant of the DCC concrete.

“In the meantime, we had feedback from other customers working with the A variant of the DCC,” explains Coskun. His summary only matched that of Ettengruber to an extent. “Most operators found the short blades ideal for their work.” On account of the wide variety of projects managed daily by the demolition companies, the crusher had to meet individual requirements.

Anyone who has to work on structures with hard concrete and a moderate content of reinforcement iron preferred the DCC-A variant with a short blade, which is exposed to less wear due to its large jaw opening. Those, however, who are mostly challenged with extreme steel-reinforced concrete like Ettengruber, preferred the DCC-C variant.

In dialogue with the customer, Kiesel and Demarec decided to meet both requirements with two series: DCC-A with a short blade and DCC-C with a long blade, both of which are available for the entire range for excavators from 14 to 80 tonnes. In the case of the long blades, the crusher is also available with exchangeable wear parts.