Flexibility in dust suppression via atomized mist

“Atomized mist technology has been an effective approach to dust management. This new development will allow users to tailor the fan speed to match the job,” said BossTek Sales manager Mike Lewis. “Project managers may need the wide coverage and long reach of our larger models on some jobs, but the volume and throw distance may be too much for smaller projects, such as those in crowded downtown locations. Instead of using a smaller machine, it is now possible to simply dial back the air flow and thus match the requirements of those smaller projects. This means that now users can dial in the speed and throw distance as their requirements change. The variability will range from just a few RPMs up to the maximum delivered by each model.”

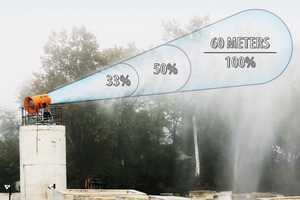

The VFD control will be available via a simple dial or remote control on three of the company’s DustBoss models: the DB-30, DB-45 and DB-60. All three use specialized nozzles and a ducted fan design to atomize the water flow into droplets 50 – 200 µm in size, which is the optimum for most dust control applications. Matching the droplets to the most common particle sizes delivers the greatest opportunity for them to collide and fall to the ground.

The variable drive is ideal for standalone applications that require flexibility, communications and energy saving options in a cost-effective solution. The modular design facilitates installation and configuration, with communications options that include a dual port EtherNet/IP card for networking flexibility. An integral LCD human interface module supports multiple languages and features scrolling text to explain parameters and codes. Flexible motor control options include volts per hertz, sensorless vector control and Economizer mode to suit a wide variety of applications.