Fluid couplings for China

The mining company Xishan Jinxing Energy Co. Ltd (Fig. 1) relies on the fill-controlled 866 TPKL fluid coupling from Voith. A total of three fluid couplings are used underground in the powerful 4.8 MW drive of the main belt conveyor in the Xiegou No. 12 coal mine in Shanxi Province/China.

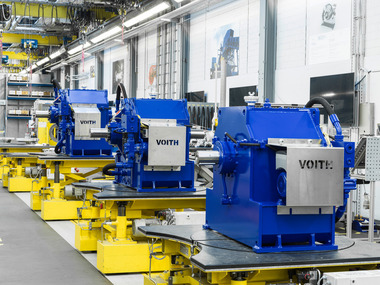

Three 1600 kW (1900 HP) drives power the 1900 m (6200 feet) long main inclined belt conveyor. This conveyor transports 3800 metric tons of coal every hour uphill. Powerful and reliable couplings are required such as the 866 TPKL fluid coupling from Voith (Fig. 2). Through controlled application of torque, the fluid coupling pretensions the belt slowly and permits smooth conveyor start-up. This controlled soft start protects the belt and driveline components and extends their lifetime. As a result, the Voith fluid coupling reduces unplanned downtime – the operator benefits from lower maintenance costs and continuous production. Regardless of the load state of the belt, start-up times of up to three minutes are possible. Thanks to stand by cooling of the operating oil, the 866 TPKL fluid coupling also permits multiple conveyor start-ups in succession, even when the belt is loaded.

The compact fluid coupling is also very capable of withstanding extreme environmental conditions such as dust, dirt, moisture, heat or cold. As in every hydrodynamic coupling, power transmission in the 866 TPKL is virtually wear-free. In addition, motors start up independent of the machine load, and through sequenced starting of the motors, the fluid coupling reduces the load on the power supply circuit. An additional benefit of the 866 TPKL is its ability to operate with reduced filling to drive an empty conveyor at a reduced speed. During the creep speed operation, less power is transmitted and the belt runs more slowly. This function is useful for the visual inspection of the belt and splices. In the Xiegou No. 12 coal mine, the fluid couplings were operated in the partially filled mode during commissioning to be sure that the belt was tracking properly. With the fluid couplings operating in the partially filled mode, the belt speed could be reduced to 1.2-1.7 m/s instead of operating at the rated speed of 4.5 m/s.

Until now, the coal mine has been operating at the initially planned production capacity of 15 million metric tons of coal per year. The operator plans to increase production capacity in the next one to two years. This will require the main belt conveyor to be upgraded with a fourth drive. For this, the operator plans on installing an additional 866 TPKL fluid coupling from Voith.