From junk pile to stockpile – X-ray dry sorting pilot trial1

Using X-ray sorter technology originally developed for waste recycling industries, NAC engineers are able to eject reject material from raw coal before it enters the coal preparation plant (CPP). NAC CPP Manager, Robert Rashleigh said the technology had also been applied to ore sorting. “While this technology is currently used in processing metalliferous ores like tungsten and nickel, our trial has shown that it can also process New Acland coal with good results,” Robert said. “Should we move forward I believe this would be the first time the technology is installed in a coal mine in Australia and we are excited by the initial results of the trial.”

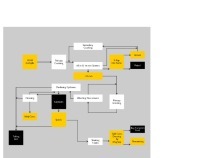

The testing of the technology was carried out at pilot scale at Steinert Australia in Melbourne, using coal sourced from NAC. The process is relatively simple in practice. A stream of sized material is fed to the X-Ray sorter, spreads out on a wide horizontal conveyor and passes between the X-Ray source and a detector. Inside the sorter, the X-Ray beam passes upward through the moving stream and differentiates particles of coal and stone, based on an adjustable sorting algorithm. As the stream discharges over the end of the conveyor, compressed air jets placed across the direction of flow are activated. Individual particles of target material are ejected out of the falling stream by the air impulse and separated from the flow. Either species can be ejected from the falling stream.

Dual energy X-Ray transmission scanners are used to measure the amount of X-Ray radiation absorbed within each particle at two different energy levels. Thereby, it is possible to calculate the average atomic density of each measured area by the controlling software, independent of the effect that particle thickness or size have on the absorption of X-Ray radiation. Thus, the sorter can distinguish a ‘coal’ particle from a ‘stone’ particle with a very high degree of accuracy. However, for the sorter to be able to determine what is coal and what is reject material it had to learn the difference.

In 2015, NAC sent a selection of hand-picked samples to Melbourne that included discrete coal and stone, taken from the raw coal stockpile. These samples were placed in the source beam so that the machine could be ‘trained’ to recognise coal and stone. The characteristics of the individual samples were read by the machine whilst stationary in the detector beam. From these readings, the machine’s separation algorithms were developed; these were used as the basis of separation when the pilot work was undertaken. In December 2016 bulk raw coal samples, in the order of six tonnes each were collected from the NAC run of mine (ROM) pad to be used in the pilot scale project. The bulk material was screened in the laboratory to produce test portions -150 + 50 mm and -50 + 25 mm with 1.5 t and 1.3 t respectively being sent to Melbourne. Although the -25 mm was not treated, 25 mm is an arbitrary size and the X-Ray sorter can treat smaller sized material. The relatively large test amounts were used to give more reliable outcomes.

The prime target outcome of the pilot trial was to remove stone from generally poor quality ROM coal and at the same time ensure that no significant quantity of recoverable coal was lost. To achieve this, a high cut point was targeted when upgrading CPP feed in order to minimise coal loss to reject. The sorting algorithm derived from the 2015 NAC test samples was used in the pilot trial and the stone was ejected from the falling stream. The algorithm was adjusted to reject only the highest mineral content particles so that coal loss to reject would be minimal.

The most effective benefit from raw coal upgrade occurs when treating the poor quality seams. There is also a potential metallurgical improvement within the separation process itself. When treating poor quality (that is low product yield) coals, the quantity of reject material that has to discharge from the Dense Medium Cyclone (the major separation device in the plant and the one which treats the coarse material) is large and can lead to some of that material reporting to product when all of it should ideally go to reject. Under such circumstances, this inclusion of reject in the product will increase the product’s ash content requiring the DMC’s separating density to be lowered in order to maintain product specification. Lowering separation density will reduce yield. For poor quality coals, where X-Ray sorting is of most benefit, removal of stone beforehand can reduce or even eliminate this effect.

Eliminating stone from the CPP feed is equivalent to an increase in plant capacity, ie. remove a tonne of stone from the feed and replace it with a tonne of coal. Put simply, using this sorting technique is attractive because it means that it is possible to put a higher quality raw coal through the CPP, which in turn means a higher yield. Basically, by sending some of the coal through this sorter first, the CPP would be doing less work getting rid of reject, and more work processing product coal. Right now the outcomes from phase one of the trial are being evaluated.

It is planned to go to the next stage of the trial and potentially bring a sorting unit onsite to New Acland. Using the new technology at the mine site will let test it on a large scale and test how it interacts with the rest of the CPP operations. The Bayswater pilot testing unit is similar in most respects to a commercial size unit, but has a 1 m wide feed belt while the commercial units have 2 m wide belts. It is intended to put the technology to use in a full scale, commercial operation.

1Article by New Acland’s, Michael Rodgers. See excerpt on re-purposing

technology to suit coal mining is becoming a speciality for New Acland Coal (NAC) engineers