Glatt Ingenieurtechnik GmbH

Glatt Ingenieurtechnik from Weimar will present a market-ready process that fulfils the legal obligation of German waste disposal companies to recover phosphorus. In the first step of the two-stage “PHOS4green” process, a suspension is produced from the phosphate-containing ash, a mineral acid and, depending on the objective, also other components. The suspension is then spray-granulated in the fluidized bed. This results in fertilizer granulates available to plants and soil, which can be discharged, filled and delivered directly as soon as the desired grain size has been reached.

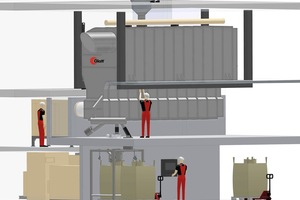

Transferring fine powders and powder mixtures into uniformly porous, practically dust-free, soluble and dosable granulates is what the new “GF ModFlex” plant concept achieves in an endless loop while consistently providing top quality and safety. Thanks to gentle process control, the plant preserves the nutritional and functional properties of the products.

With this compact modular system, Glatt addresses manufacturers who want to upgrade or renew their machinery at short notice and under limited space conditions, and who want to reach production volumes of 100 – 3000 kg/h. Furthermore, the Atex-compliant concept, equipped with WIP cleaning, scores with an extremely short installation time of only 12 days and an integrated room and zone concept.

Another highlight presented by Glatt is the continuous powder synthesis method: APPtec®. Using spray calcination in a pulsating hot-gas stream at temperatures of 200 – 900 °C, powders with particularly narrow particle size distributions can be produced from a wide range of starting materials. The unique and easily controllable thermodynamic process conditions make it possible to precisely adjust the product properties – for example with regard to chemical composition, morphology, phase structure and coating or surface chemistry. In addition to the joint development of APPtec®-based powders and contract production, Glatt also offers reactors of the ProAPP® series in various size – even for production on a laboratory scale.

Hall 3 / 249