„GreenScreens“

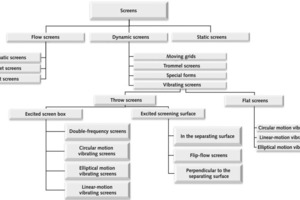

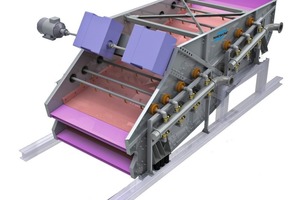

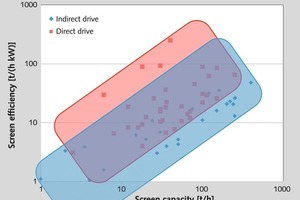

What does a screen really cost?Summary: Which criteria are decisive when purchasing a screening plant? In addition to the investment costs of screens, the running costs over their years of service should be taken into account in any buying decision. In addition to the unavoidable maintenance, one key if not obvious cost driver is the energy consumption of the type of screen used. In the following, the total cost of ownership of different types of screen is considered.

1 Motivation

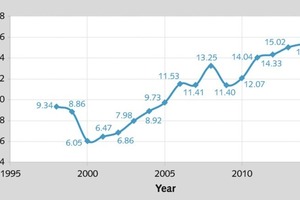

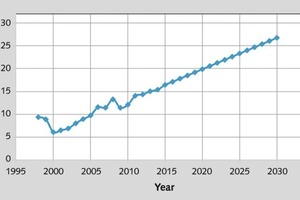

In times of generally rising energy costs, besides the costs for basic fuels, such as coal, oil and gas, the costs for secondary fuels, for example electric power, are also increasing. The latest developments show that especially in Germany, on account of the energy transition introduced in the country, the costs for power will increase disproportionately at least in the mid-term. Whether the additional extraction of shale gases, about which frequent reports appear in the media, will significantly combat this price trend, seems questionable. Accordingly, plant operators should...