Long distances, high performance

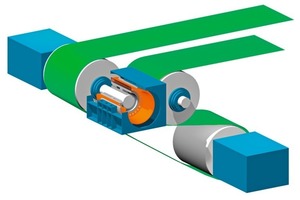

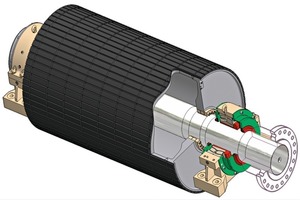

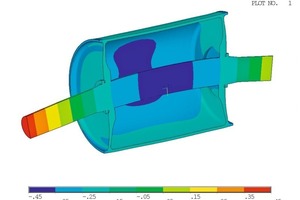

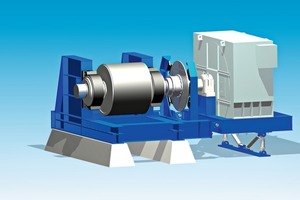

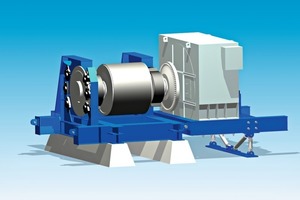

Gearless Drives for High Capacity Belt ConveyorsSummary: Belt conveyors in hard rock mining determine the development of belt conveyor components on the high end of their performance spectrum. New requirements with regard to conveyor geometries and mass flows make it necessary to think about alternative drive concepts. When it comes to drive sizes exceeding 3500 kW per individual drive, there are no conventional electromechanical drives with electric motors and helical bevel gears. Gearless drives, like those which are state of the art for the mine hoists implemented in underground mining operations, allow the use of larger drive units and are increasingly being utilized to drive belt conveyors.

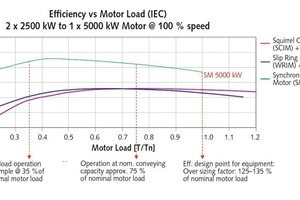

Individual belt conveyors in hard rock mining operations all over the world can nowadays extend over distances of up to 16.8 km and overcome height differences of up to 500 m, while normally achieving outputs of approx. 12 000 t/h. Such belt conveyors have had a significant impact on the development of individual components. Conveyor belts with strength of up to 7800 N/mm are still in use today. Electromechanical drives, consisting of electrical motors (wound rotor or squirrel cage motor) and helical bevel gears with a capacity of up to 3150 kW, are currently in use in South American copper...