Longer Service Lifetime

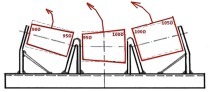

With the simple lagging of top and bottom run idlers with NILOS wear protection rubber covers (Fig.) the service lifetime of the idlers can be lengthened considerably. The field-proven material types NILOS RB lagging and NILOS RX Reflex lagging are available in hose form to be attached with steel mounting sleeves to all top and bottom run idlers. The lagging can be simply fitted in a cold adhesive process with the two-component adhesive, NILOS TOPGUM TL-T60/TL-T-70, together with NILOS SH primer. The NILOS range of idlers extends from bulk solids belt conveyor idlers and the corresponding troughed belt idler units right to idler garlands. These are available with and without buffer rings, support rings and support ring packages. All conveyor belt idlers can be supplied with or without rubber cover.

Info: www.Nilos.com