Metso service check for screening machines

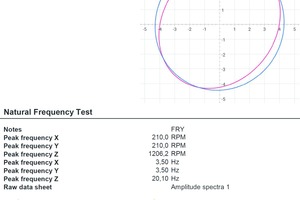

In the analysis of the vibration behaviour, both the type (circular, elliptical or linear) as well as its amplitude and the resulting G-force are in the foreground with the speed and direction of rotation. These factors determine the transport speed, the contact frequency and material distribution on the respective screen decks and the quality of the end product. In the ideal case, the speed, vibration amplitude and the degree of inclination of the machine are so optimally matched to the screening media used and the grain shape of the material that, when producing under material, it is operated outside the destructive natural resonance of the vibrating structure.

In order to measure and analyze vibrating screens accurately, Metso has developed ScreenCheck®, a portable test instrument with wireless electronic and magnetic sensors and corresponding automated software, which Metso service technicians use wherever necessary. For analysis, the service technician attaches the transducer of the magnetic tester to defined points on the side walls of a screening machine to determine the characteristics of the vibration transmissions and their consequences. A comparison of the left and right orbits provides information about the required symmetry of the vibration behavior of circular oscillators, for example. With the so-called “bump test” as a further functional check of ScreenCheck®, the focus is on determining the natural frequency and the corresponding critical speed. With Screencheck®, conclusions can be drawn as to whether the machine is already operating under ideal conditions or whether service, adjustment of parameters or replacement is required.

According to Metso, regular inspection with ScreenCheck® helps to ensure that screening machines always operate at consistently high operating efficiency, minimizing wear and tear and extending the life of a plant. The test equipment is used for factory acceptance tests, on-site commissioning or for regular or general maintenance or inspections. The menu quickly guides the experienced service technician through all available and recommended tests. Metso ScreenCheck® is suitable for all brands and makes.

//www.metso.com" target="_blank" >www.metso.com:www.metso.com