New requirements concerning exploders

Since the middle of June 2014, the “Zement- und Kalkwerke Otterbein GmbH & Co. KG“ have been in the phase of practical testing of the Ontaris Explosives Stock Book. Otterbein, in close cooperation with the MAXAM company, are the first in Germany to adopt Track and Trace with electronic stock accounting in standard operation.

The Zement- und Kalkwerke Otterbein are situated between Vogelsberg and Rhön (Fig. 1). The company was established in the Lauterbacher Graben about 100 years ago, as a merger of several smaller lime kilns. Today, Otterbein extracts almost 500 000 t of lime each year. This production output requires blasting every two to three days (Fig. 2). Therefore, the new EU Directive on the identification and traceability of explosives also applies to the Zement- und Kalkwerke Otterbein.

For this reason, Bernhard Pfohl, head of the quarrying site and blasting officer, quite early began to deal with the new requirements, which will come into force in April 2015. Since autumn 2013, he has been looking for a suitable solution which would enable him to meet these new requirements. Apart from complying with the EU identification directive, it should be ensured that its operation does not require internet connection, since the warehouse is not equipped with the respective installations. The devices used must comply with the recommendations of the BAM (German abbreviation for Federal Institute for Materials Research and Testing), which guarantee that use in explosives warehouses is possible without any risk. Moreover, authorities must approve the solution as a substitute of the previous stock book. Furthermore, running costs should not occur and, if required, it should be possible to change the supplier without problems. Another important factor was that no major changes would be required in the current work flow, but the new solution should allow the integration into existing processes. Otterbein wanted to utilize this identification obligation to switch from an explosives stock book in paper form to the new electronic version.

With the explosives stock book from Ontaris, consisting of a 9“ tablet computer with a handy Bluetooth scanner, they found the respective standard solution on the market which met their requirements.

First national pilot operation

The Ontaris explosives stock book was used for the first time in the Otterbein quarry at the end of June, 2014. About every two weeks, a consignment of explosives which on average comprises 2 pallets each, arrives at the quarry. Since that time, they have been constantly working with the electronic explosives stock book.

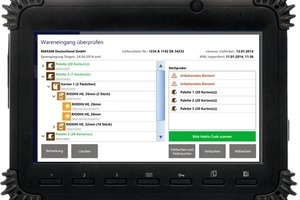

The electronic stock book, consisting of a tablet computer and the Bluetooth hand scanner, has been completely configured by Ontaris so the first explosives consignment from MAXAM could immediately be recorded by the new system (Fig. 3). On the dot of 7 o’clock, the ordered explosives were delivered to the explosives warehouse. Immediately on arrival, Pfohl, as he did before, checked the consignment against the bill of delivery on paper.

For the sake of traceability of the explosives and in order to enable electronic stock accounting, the driver brings along a supplier file in XML-format, which contains the list of all identifications numbers of the articles and packaging contained in the consignment. For simplicity reasons, this file was saved on a USB stick. The software imports the file and the USB stick is directly returned to the supplier.

To ensure that the numbers of crates or articles of the supplier’s XML file really correspond to the actual consignment, Bernhard Pfohl carries out a random sampling by using the scanner. He scans all crates to make sure that they are all correctly included in the supplier file. It is very unlikely that the content of these crates does not correspond, as they have not been modified after production. As far as the prefabricated bundle of detonators are concerned, the error probability is higher due to manual packaging. For this reason, Pfohl opens the packaging and manually examines the articles contained therein. After the successful sampling, he records the item in the stock book.

“This extensive goods receipt hardly takes 5 minutes and now I do not have to keep a stock book on paper or finish work on the PC in the evening. This saves a lot of time”, says Bernhard Pfohl. With registering the goods received on the tablet computer, the stock book is updated, too. “Now, if the responsible technical inspector comes to see me in the quarry, I can immediately provide proof of the stock without any further cost or effort.”

When the goods are stored in the warehouse, he chooses the exploders for the next blasting and scans them. He loads them into his car and drives to the blasting site. He also appreciates the simple possibility to again include articles with unreadable labels. Due to the pollution on the blasting site labels are easily destroyed and then bar codes can no longer be read. In case some articles were not used for blasting, he returns them to the stock afterwards and carries out the return confirmation. For this purpose, he simply scans the article again which is thus registered in the stock book.

“The return of cord is made really easy. I scan the reel and a field appears on the screen. I enter how much I have consumed and the system independently calculates how much cord will remain on the reel”, says the head of the quarry (Fig. 4). After three months of intensive use of the Ontaris stock book for blasting means, Pfohl is convinced: “The software is easy to operate, very clearly structured and works reliably.”

//www.ontaris.eu" target="_blank" >www.ontaris.eu:www.ontaris.eu

//www.zkw-otterbein.de" target="_blank" >www.zkw-otterbein.de:www.zkw-otterbein.de