Replacement at the point

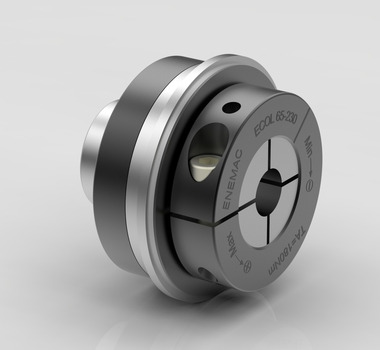

Tsubaki has introduced a wear indicator for large pitch chain drive sprockets which provides a clear indication of wear, allowing the sprocket to be replaced before it fails. Eliminating the guesswork traditionally associated with wear checking, the indicator protects investment in capital equipment, eliminates breakdowns and allows better management of maintenance scheduling.

Modern sprockets, such as those from Tsubaki, offer long life, reliable performance and the ability to withstand shock loads. However, they will still wear over time, with the tooth profile changing shape and no longer fully supporting the roller drive chain. Gradually the rate of wear of both sprocket and chain accelerates, resulting in loss of tension, jumped chain, drive slipping and catastrophic failure.

Because all of this happens over an extended period of time, it is very difficult to see the amount of wear that has occurred. In the worst case scenario, a high load drive could fail catastrophically possibly resulting in injury to personnel, damage to equipment and loss of production due to extensive downtime.

Identification of wear

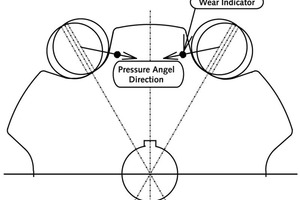

Tsubaki’s Wear Indicator provides a simple and effective solution to this notoriously difficult problem. Wear pins are positioned on the thrust face of the sprocket teeth adjacent the point where the drive chain will exert the most pressure. In use each tooth wears towards the pin and by measuring the distance between the tooth edge and the pin, wear is assessed and an objective decision on sprocket replacement can be made.

Where downtime is not an option, the patented wear indicator technology offers user the ability to identify and schedule drive system maintenance before critical failure occurs, based on actual sprocket wear rates. Benefits include reduced overall cost of equipment ownership, and extended chain life through predictable maintenance.