TSUV Gyratory Crusher delivers safety and productivity benefits

TSUV Gyratory Crusher

TSUV Gyratory Crusher

© FLSmidth

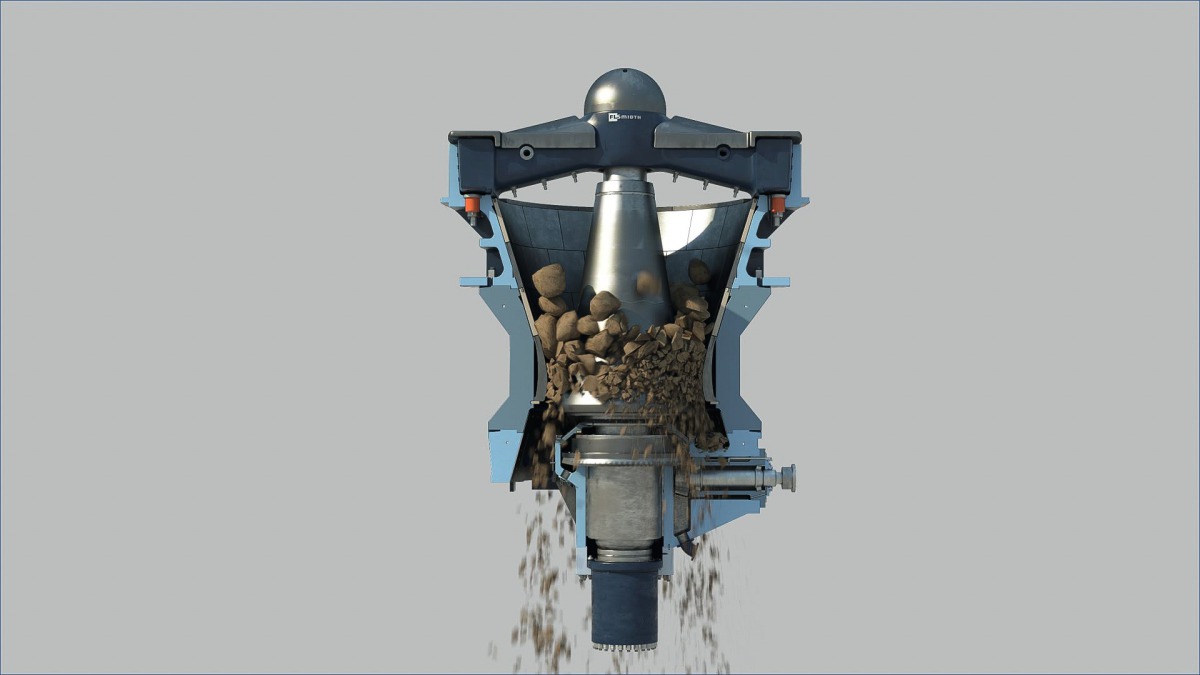

The top-service design prioritises safety, easy maintenance and efficient crushing performance. Unlike other gyratory crushers, which require workers to get in underneath the crusher to perform high-risk maintenance, the TS range allows service and maintenance to be carried out from above, increasing speed, safety and simplicity. Additionally, the 100+ tonne, fully-dressed main-shaft no longer needs to be guided into the eccentric assembly by hand. Now, the shaft aligns automatically, dramatically reducing risk.

All TS Gyratory Crushers are built for strength, durability and the ability to adapt to the various requirements of mine operators. But the TSUV Gyratory Crusher design adds even more power, capacity and flexibility, to give mine operators a low total cost of ownership.

Higher power: Improved power handling capabilities allow operators to process more material as ore yields decline, enabling you to remain competitive. The crusher footprint has only nominally increased but maximum power handling is now up to 1500 kW.

Higher capacity: Improved capacity throughputs make use of the additional power available without compromising on setting or product size. You get the same product – but more of it.

Optimised speed: Optimised eccentric speeds ensure maximum throughput without incurring excessive wear rates. This is a finely balanced equation, based on extensive R&D work, which together with the new service and operational features, gives operators the lowest possible cost per tonne of material processed.

To offer even greater potential to optimise performance, the TSUV Gyratory Crusher is digitally enabled – giving operators more control over operations and availability. The ability to make fine adjustments to wear compensation, track equipment trends and instantly detect crusher obstructions will enable increased uptime, optimum equipment life and significantly reduce risk of unplanned downtime.

The TSUV Gyratory Crusher can be connected to FLSmidth’s digital ecosystem, which provides operators with the benefits of both FLSmidth technologies and experience. A range of services is on offer, geared towards maintaining asset health and optimising performance, many of which can be carried out remotely, saving both time and money.

The TSUV Gyratory Crusher’s advanced control system gives operators a 24/7 view of performance metrics, enabling increased reliability. And, with further condition monitoring feedback and controls, maintenance can be more proactive, minimising the risk of unscheduled stops.

Through a combination of all these features, the TSUV Gyratory Crusher achieves very low cost per metric tonne in operation and gives operators a low total cost of ownership. This translates into a reduced environmental impact. “We remain steadfast in our aim to reduce emissions from mining to zero by 2030,” says Chris Reinbold, Head of Global Product Line Management, Senior Vice President, Mining. “Increasing the sustainability of key equipment like the gyratory crusher is part of our core goal to invest in efficiency-focused R&D.”