Wireless solution for level measurement in portable tanks

Thanks to digitalization, production system users don’t just receive more or better data for analysis. The new solution from Endress+Hauser means they even have access to data that they have been unable to capture so far. In combination with the Netilion IIoT ecosystem, the FWR30 level sensor makes it possible to measure the fill levels in portable containers where this task has not been possible until now. After one-time commissioning, the world’s first 80 GHz radar level sensor, which can be mounted on intermediate bulk containers (IBCs) in a matter of minutes, sends the measurement values to the cloud at regular intervals using wireless technology.

To date, IBC operators could only approximate the levels in the containers for these applications since they couldn’t be automatically measured. This also applies to the suppliers and distributors responsible for ensuring the availability of the stored media in the IBCs at the production sites. In cases where the fill levels still needed to be determined, the employees had to drive to all of the IBCs and manually carry out the measurements, a time-consuming activity that furthermore supplied no data down to the minute, hour or even day. For operators, transparency regarding the fill levels or inventories is important. IBCs are typically used at sites where there is little opportunity to carry out measurements, either due to a lack of cable connectivity to the process control system or because running dedicated cables for the level measurements is too costly. In combination with the Netilion IIoT ecosystem, the Micropilot FWR30 makes it possible to have access to the fill levels and know where the container is currently located, at any time and from anywhere. This wireless instrument runs on battery with a battery life of up to 15 years.

Digital measurement point in three minutes

The instrument design and the wireless connectivity to the cloud via the mobile phone network makes set-up and digitalization of the measurement point extremely fast and easy, even when compared to the commissioning of a conventional level measurement point connected to the process control system. After three minutes of installation and set-up work, the data is visually available, accessible via the cloud and ready to be utilized by various applications. Another reason why the installation is so quick is that the instrument requires no cabling and operates entirely via wireless communications. If required, the instrument can also be removed from the IBC, for example to swap out the battery. An intelligent monitoring system for liquids can thus be established with little effort.

Level measurements via high-end 80 GHz radar

technology

The non-contact measurement is based on 80 GHz radar technology. The instrument’s microwave beam penetrates the plastic tanks and supplies highly reliable measurement values. Even if foam build-up occurs in the tank, the measurements are not influenced. As well as the level measurement value, the instrument provides the position of the tank via the mobile phone network. The location information is reliable even when multiple IBCs are stacked on top of one another. The Micropilot FWR also features a sensor for measuring the outside temperature. And the battery status is sent to the cloud as well.

Cloud connectivity via the mobile phone network

The Micropilot FWR30 sends the data via the mobile phone network. The measurement data, as well as other information captured by the instrument, is then transferred to the cloud where it can be retrieved via mobile end-user devices or desktop PCs from anywhere and at any time. The cloud connection requires no additional equipment and no separate cabling. The solution relies on a “cloud only” approach without any connectivity to the process control system.

Netilion IIoT ecosystem: software for various application scenarios

A vital part of the level measurement solution for mobile tanks is the Netilion IIoT ecosystem, which accesses the data stored in the cloud, processes it so that it can be used for various application scenarios and also utilizes it as a basis for further calculations. The Netilion applications are offered as part of a “freemium” model, allowing users to connect up to five measurement points at no charge. Costs are incurred for additional measurement points. Users enjoy the flexibility to choose from a broad service portfolio consisting of three modules: Netilion Value, Netilion Inventory (coming soon) and SupplyCare Hosting. They can also successively adapt the services to their own needs.

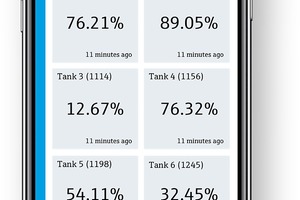

Netilion Value: overview of the measurement values and instrument parameters

The simplest application scenario is the digitalization of the level measurement point to maintain an overview of the measurement values in various IBCs. These applications, which are covered by the Netilion Value module, involve simply bringing the measurement points into operation, after which the fill levels can be visualized clearly. The functions range from information regarding the current measurement values to historical data that allows users to track the development of the fill levels over time. Information related to the position of the tanks, instrument and battery status, as well as the ambient temperature, can be retrieved as well. Fill level alarms can also be set up so that users are notified if the minimum or maximum levels, which users have the freedom to configure, have been reached. Additional measurements points can be added with just a few clicks. The data is then immediately available right after commissioning.

Netilion Inventory: simple and clear inventory

management

Compared to Netilion Value, Netilion Inventory offers expanded functionality. Beyond the simple display of measurement values, Netilion Inventory also enables simple and clear inventory management, which is realized with a function for calculating the volume of the IBCs. Netilion Inventory can also generate forecasts for calculating free storage capacity. This application thus offers more information about the status of tanks, silos and containers.

SupplyCare Hosting: profit tool for comprehensive inventory management

Users who are looking to monitor more complex logistics chains and forward the measurement data to third parties, such as suppliers, customers or partners, will find a high-performance tool in the SupplyCare Hosting module. It offers a range of functions beyond what is available with Netilion Value and Netilion Inventory, including role-based user management and the ability to configure third-party access rights. Apart from displaying the event history, SupplyCare Hosting also provides an overview and analysis of the key parameters such as average inventory, efficiency or the inventory turnover of the transported liquids. To increase the efficiency of the logistics processes, SupplyCare Hosting enables user-friendly requirements planning. Another feature of this software solution is that the data can be synchronized with all common ERP systems.

Digitalizing measurement points has never been so easy

The wireless solution recently introduced by Endress+Hauser for the digitalization of level measurements using the 80 GHz radar-based FWR30 in conjunction with the Netilion IIoT ecosystem is remarkably simple. The modular offering provides scalable solutions for various application scenarios, especially for portable IBCs. This allows the secure transfer of information regarding the fill levels, position of the tanks, outside temperature and instrument and battery status to the cloud, where it can be retrieved at any time and from anywhere. The solution is thus well suited for the cost-effective digitalization of level measurement points and supplies reliable data where once only assumptions were possible.