DFT GmbH Deichmann Filter Technik

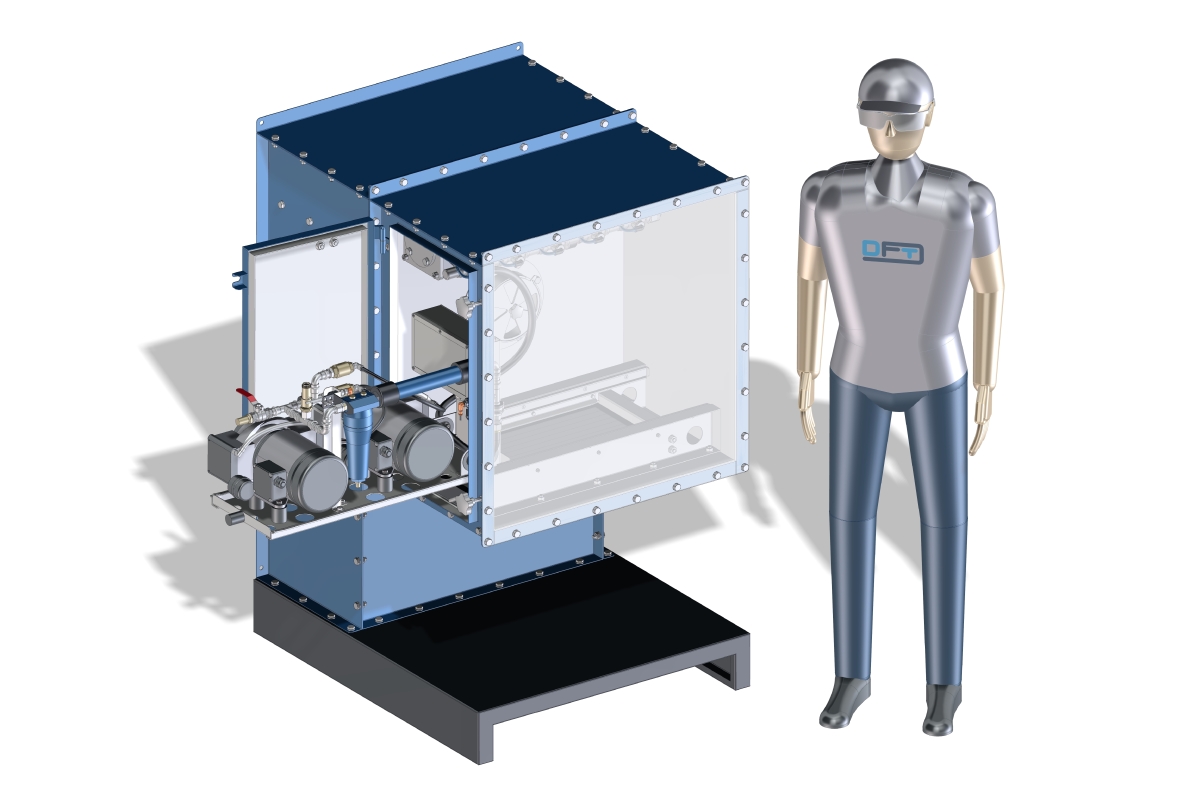

1 Trade fair model for POWTECH TECHNOPHARM

1 Trade fair model for POWTECH TECHNOPHARM

© DFT GmbH

In industrial dust extraction systems, compressed air cleaning is one of the biggest energy consumers. Conventional systems operate at high pressures (often 6 bar and above) and generate considerable energy expenditure due to throttling losses at valves and nozzles. This is where DFT’s new solution comes in – with an intelligent system design that relies on controlled compressed air pulses and demand-based control.

Targeted compressed air pulses instead of wasted energy

The actual cleaning effect only occurs in the first few milliseconds of a compressed air pulse – precisely when the pressure is at its highest. However, conventional valves close slowly via a pressure equalisation bore. This means that the compressed air continues to flow even though it no longer has any effect on the cleaning process – consumption increases, but the benefit does not.

This is where DFT’s new solution comes in: the patented diaphragm valve is closed pneumatically so that it closes precisely and instantly as soon as the cleaning effect is achieved. This means that only the truly effective amount of compressed air is used – saving up to 40 % of compressed air consumption.

2 Interior of the airbox

© DFT GmbH

Intelligent control and innovative compressed air generation for maximum efficiency

Another advantage is the intelligent control system: the degree of contamination of the filter elements is measured using differential pressure measurement. The control system then automatically adjusts the cleaning intervals and the performance of the compressor. This means that cleaning only takes place when it is really necessary – a decisive contribution to energy savings and longer filter service life.

The system becomes even more efficient with the optional integration of the Airbox: instead of connecting the filter to a central compressed air network with long pipes and potential leaks, the compressed air can be generated directly on site.

The airbox comprises one or two diaphragm compressors (depending on requirements), a diaphragm dryer, the complete compressed air installation, intake filtration and the control system for the compressor and filter cleaning. The result: lower energy consumption, demand-oriented compressed air generation and significantly higher operational reliability – without the typical losses associated with central compressed air systems.

Conclusion: Sustainability meets cost-effectiveness

With this development, DFT GmbH is setting new standards in industrial filter cleaning. The combination of technical precision, energy-efficient design and intelligent control makes the solution particularly attractive for operators who want to reduce their operating costs while contributing to sustainability.

Booth 10-538 (VDMA joint stand)