Enhancing efficiency and reliability with MAAG KA gearboxes

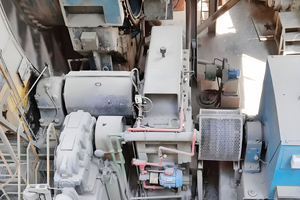

Replacement onsite

In a busy mineral processing plant, the reliability of equipment is paramount to maintaining productivity and minimizing downtime. One such instance involved the replacement of an aging gearbox in a critical ball mill. The existing gearbox had been in operation for over a decade, showing signs of wear and inefficiency. The plant’s maintenance team decided to replace it with a MAAG KA gearbox, known for its durability and performance. The installation process was meticulously planned to ensure minimal disruption to the plant’s operations. With the new gearbox in place, the ball mill’s performance improved significantly, leading to smoother operations and reduced energy consumption.

MAAG KA benefits

The successful replacement not only enhanced the mill’s efficiency but also resulted in substantial cost savings. The new MAAG KA gearbox required less frequent maintenance, reducing both downtime and operational costs. The plant’s management was impressed with the seamless transition and the immediate benefits observed. The assembly process went very smoothly, and the customer was extremely satisfied with the outcome. This case stands as a testament to the importance of investing in high-quality, reliable equipment to ensure long-term operational success and efficiency in mineral processing.

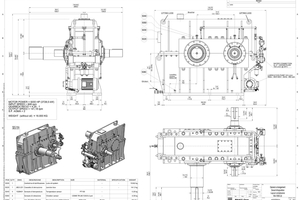

Technical description of KA gearboxes

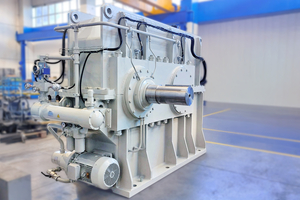

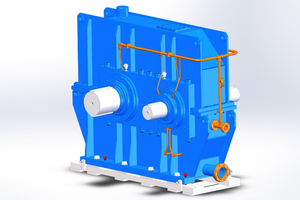

KA gearboxes are specifically designed to drive ball mills and SAG mills in the mining and cement sectors. Engineered for a long lifespan exceeding 60 000 hours, these machines can be customized and upgraded to meet customer requirements. Built to withstand the harshest conditions, KA gearboxes ensure reliable performance even in the most demanding environments.

Key benefits of KA gearboxes include:

High flexibility to replace old gearboxes from other brands

Easy maintenance, reducing downtime and operational costs

High efficiency, leading to improved energy consumption

Compact design, optimal for demanding milling applications

Reduced maintenance and operational costs, ensuring uninterrupted production

These gearboxes are the perfect solution for enhancing productivity and reliability in mining and cement operations. Whether you need a standard model or a customized solution, KA gearboxes deliver exceptional performance and longevity.

MAAG’s commitment to service excellence

MAAG is committed to providing responsive, reliable, and always-prepared service excellence. MAAG’s service engineers are ready to deliver swift solutions all around the world, whenever needed. With specialized expertise in gear units, the MAAG team ensures efficient on-site support to minimize downtime and maximize operational continuity.

Comprehensive service offerings

MAAG offers a comprehensive range of services to support customers throughout the lifecycle of their equipment:

Customer service: From installation to start-up, MAAG’s customer service team is always at the side of the customers, ensuring the best possible service level while building up local know-how based on long-term customer relationships.

Installation and commissioning: Tailor-made plans covering installation and commissioning are devised specifically to suit customer’s needs. Experienced service engineers ensure smooth gear unit start-up.

Replacements: MAAG provides high flexibility to replace old gearboxes from other brands, ensuring seamless integration and improved performance.

Preventive maintenance: Regular maintenance schedules are designed to prevent unexpected breakdowns and extend the lifespan of the equipment.

Repair service and overhaul: MAAG’s repair and overhaul services are aimed at restoring the gear units to optimal condition, ensuring reliable performance.

Training: MAAG offers training programs to equip the customer’s team with the necessary skills to maintain and operate the gear units effectively.

Industrial maintenance with MAAG gear’s Condition Monitoring System

In the era of digital transformation, industries are increasingly adopting advanced technologies to enhance efficiency, safety, and productivity. One such innovation is the Condition Monitoring System by MAAG Gear, which supports setting new standards in industrial maintenance and operational excellence.

Predictive maintenance and optimization

The Condition Monitoring System adopts a predictive approach to maintenance. By analyzing data trends, it can predict when maintenance is required, allowing for better planning and optimization of production processes. This predictive maintenance strategy ensures that spare parts are managed efficiently, reducing inventory costs and ensuring that parts are available when needed.

Support and holistic expert maintenance

One of the standout features of MAAG Gear’s system is the access it provides to the expertise of MAAG Gear specialists. Each condition monitoring report triggers a series of actions across various departments (R&D, Technology, Spare Parts, Tendering Team, and of course, Service) within MAAG Gear, ensuring a holistic approach to maintenance. This integrated response helps address maintenance issues comprehensively, enhancing the overall reliability and performance of the equipment. This unique approach sets MAAG Gear apart by ensuring that every aspect of maintenance is meticulously managed and optimized.

MAAG provides high-precision solutions that respond to this need and enhance the productivity, sustainability, and reliability of the clients’ operations in cement, mining, and beyond. MAAG’s goal is to minimize downtime, maximize operational continuity, and ensure long-term success for the customers.