Spaleck GmbH & Co. KG

SPALECK will present innovative solutions for the pharmaceutical, chemical and food industries as well as for recycling at POWTECH 2023. The manufacturer of conveying & separation technology is presenting several innovations at once.

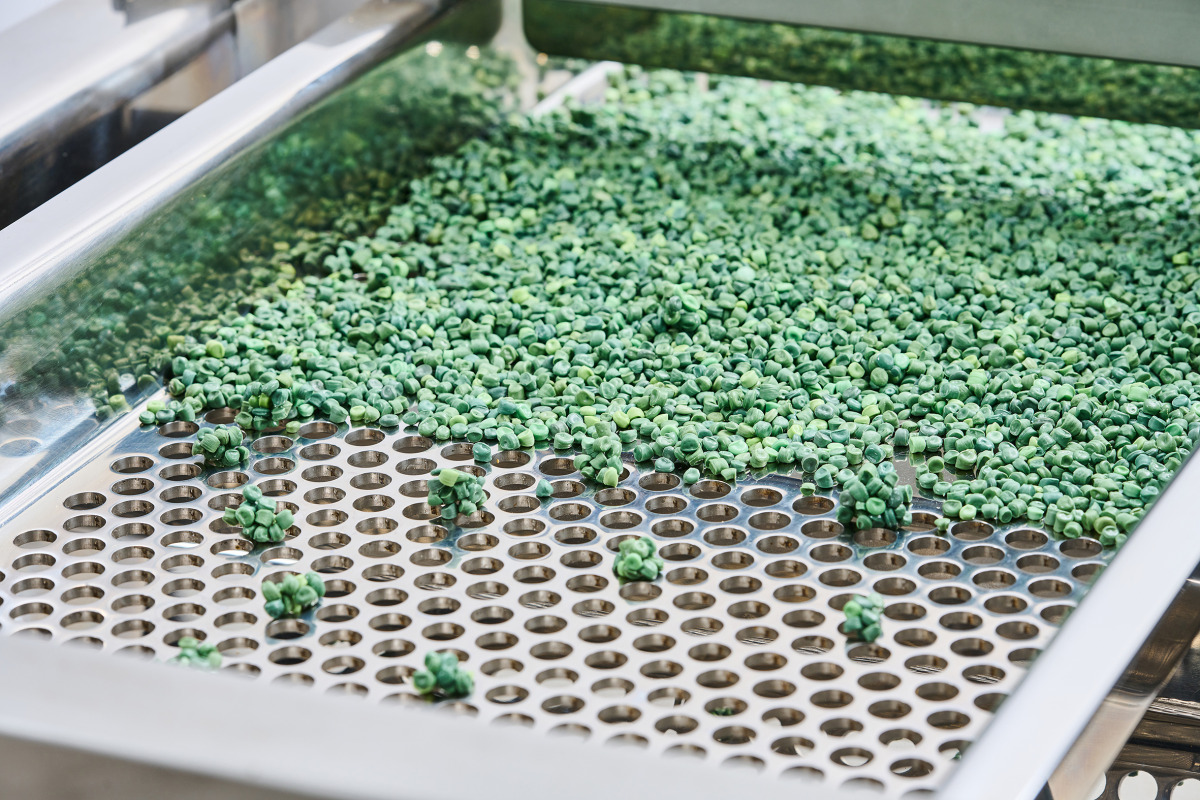

1 SPALECK screening technology for the pharmaceutical, food and chemical industries

1 SPALECK screening technology for the pharmaceutical, food and chemical industries

© Spaleck

The SPALECK AnalysisSTATION enables companies to carry out material analyses in-house. The mobile analysis unit has an integrated conveying and screening section. This makes it very easy and at the same time precise to find the optimum screening cuts and parameters for subsequent processing. The AnalysisSTATION can be flexibly adapted to different bulk solids and screening materials. Thanks to easy-to-change screen panels and an adaptable machine setting, the AnalysisSTATION is ideal for analysing and optimising your own process steps.

The SPALECK ActiveFEED feed hopper offers intelligent material feed. It monitors the desired discharge rate and automatically adjusts the oscillation parameters. Even with changing fill levels, e.g. in metal recycling, the discharge rate remains almost constant. The ActiveFEED hopper thus ensures an optimal and profitable supply of downstream aggregates.

2 The SPALECK ActiveFEED feed hopper enables an optimal and profitable supply to the downstream sorting equipment

2 The SPALECK ActiveFEED feed hopper enables an optimal and profitable supply to the downstream sorting equipment

© Spaleck

The SPALECK ActiveFLOW vibratory feeder offers precise material feeding and distribution, including control screening if desired. The integrated screening section allows for efficient removal of impurities. The oscillation width of the machine is infinitely adjustable. SPALECK ActiveFLOW is ideal for applications where precise material feeding and reliable screening are important.

The SPALECK ComfortLINE offers high-quality stainless steel screening machines and feeders with maximum ease of use. The intelligent machine design enables outstanding screening quality, high conveying capacity, user-friendliness and easy cleaning. In GMP standard, the products are additionally characterised by polished surfaces (up to Ra < 0.2 μm), rounded edges and welds to avoid dead zones as well as CIP cleaning on request.

Booth 1-316