Wire meshes for separating particulate secondary building materials

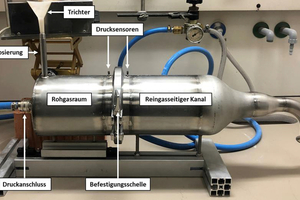

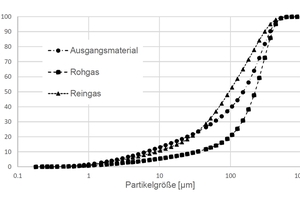

Due to their design, wire meshes are a combination of surface and depth filters. With suitable fluids, the systems can be cleaned after a certain number of operating hours and then reused. Wire meshes are therefore very well suited for separating particle systems with a wide size distribution and sufficiently coarse particles. This paper shows that effective separation is possible for mixed construction waste.

1 Introduction

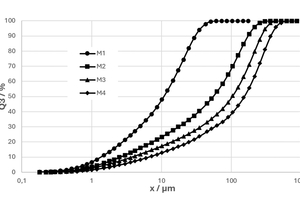

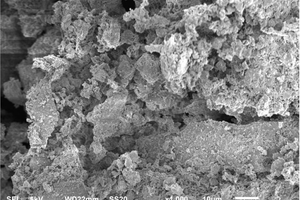

Wire meshes are generally used for droplet separation and for separating liquid/liquid systems [1-4]. However, as this article shows, these wire meshes can also be used very effectively for separating coarse-grained and irregularly shaped particle systems. Wire meshes can be used with excellent separation performance in the recycling of building materials, the processing of plastics or renewable raw materials, and in the agricultural sector, for example. Mineral bulk materials and secondary raw materials from the construction and ceramics industries very often have a broad...