Brand-new skirting system controls conveyor dust emissions

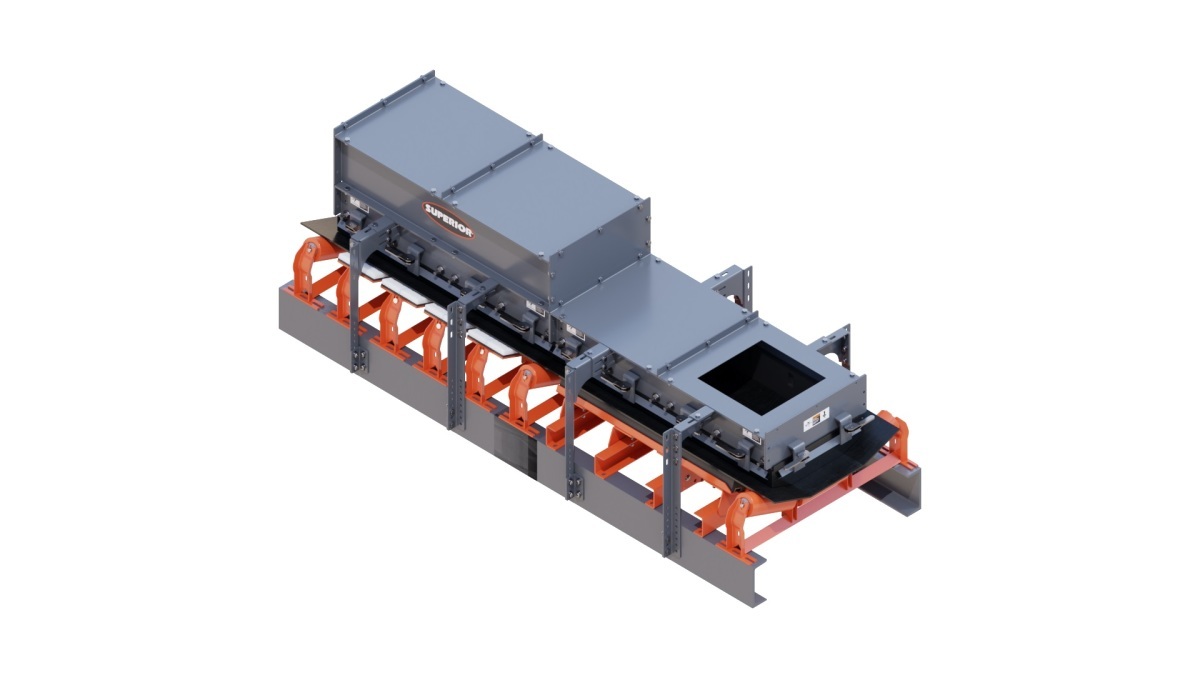

19.01.2023Superior Industries, Inc., a US-based manufacturer and one of the global suppliers of bulk material processing and handling systems, recently completed development of a brand new Modular Skirting System. The easy to install accessory controls dust and prevents spillage within conveyor load and transfer zones.

Superior skirting system

Superior skirting system

© Superior

“Our crews visit and collect data from thousands of conveyor systems each year and we figure about half of them would benefit from material containment components,” says Paul D. Schmidgall, chief engineer in Superior’s conveyor components division. “That’s one out of every two conveyors spilling valuable material, spewing harmful dust, and creating unsafe work environments.”

The new Skirting System retrofits to any brand of existing structure with little or no field fabrication. Two sets of adjustable legs aid in this universal installation. Additionally, easy to adjust clamping mechanisms are used in place of nuts and bolts to hold skirtboard rubber tight against the belt. An optional stilling zone is available to accelerate the settling of dust while material is moving inside the system.

Superior’s Modular Skirting System is sold in 1.5 m sections for conveyor belt widths up to 1,728 mm. Along with 250-tons of other products, this new Skirting System will be shown in Silver Lot booth #5006 at CONEXPO-CON/AGG 2023.