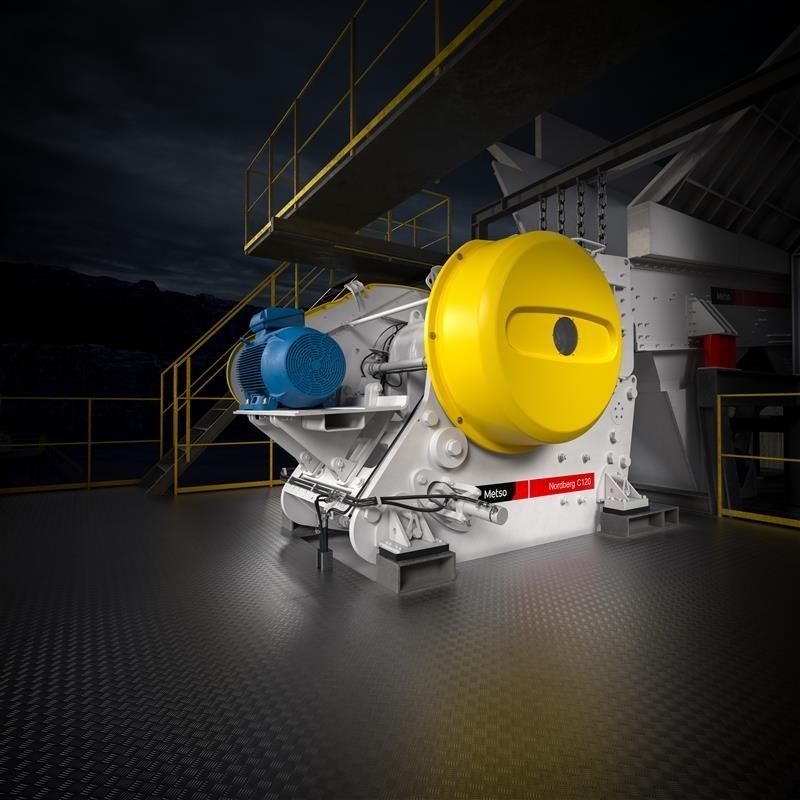

Metso celebrates 50 years of Nordberg C Series jaw crushers – a legacy of reliability in primary crushing

31.10.2025Metso celebrates the 50th anniversary of its iconic Nordberg® C Series™ jaw crushers – a globally trusted solution in primary crushing applications in aggregates and mining.

Introduced in 1975, the Nordberg® C Series™ was developed by a team of engineers in Tampere/Finland, to bring a new level of performance and durability to jaw crushers. Based on advanced engineering research rather than traditional rules of thumb, the C Series quickly set a new standard in the industry with its modular design, and optimized crushing geometry that revolutionized the market.

Metso Nordberg C Series

Metso Nordberg C Series

© Metso

Since then, Metso has delivered over 13 000 Nordberg® C Series™ jaw crushers worldwide. Known for their reliability, safety, high performance, and long service life, the crushers have become a cornerstone of primary crushing operations in aggregates quarries, mining sites, and industrial installations globally.

The first innovative Nordberg® C Series™ crushers had non-welded, bolted frame construction and aggressive motion, ensuring optimal material flow. Since the original design the C Series™ has evolved with a range of user-friendly features that enhance safety and simplify maintenance, reducing downtime. Significant advancements in automation and digital connectivity have further transformed the C Series™, enabling more efficient crusher control and condition monitoring.

“The success of the Nordberg® C Series™ is based on decades of listening to our customers, refining the design, and staying ahead of industry demands,” says Tuomas Takalo, Global Product Manager at Metso. “It’s a product that has proven itself over generations. A trusted choice worldwide, our machines continue to deliver tons safely and reliably, day in and day out. We are proud of the development work we have carried out at Metso together with our customers. Just as in the original design, our product development today is guided by a deep understanding of customer needs, data-driven insights, and thorough testing at Metso’s research and testing facilities.”

Decades of experience behind the Nordberg® C Series™ extend well beyond the crusher itself, shaping the design of Metso's OEM wear parts to deliver maximum performance and uptime. The comprehensive range of wear part profiles and alloys means that customers can find the ideal solution for their specific feed material and end-product requirements while achieving the lowest cost per ton.

To ensure the Nordberg® C Series™ continues to deliver value throughout its lifecycle, Metso provides comprehensive support through its global network of service experts and parts distribution centers. This ensures fast response times, expert maintenance, and ongoing operational reliability wherever our customers operate.

Find out more about Nordberg® C Series™ jaw crushers here .