New Eriez® Hybrid Wet Drum Separators achieve unsurpassed magnetic recovery in heavy media circuits

12.07.2022Eriez® introduced its new Hybrid Wet Drum Separator, developed to enhance magnetic recovery in heavy media circuits. The hybrid element uses ceramic and high energy rare earth magnets in the circuit to deliver 60 % higher gauss in the separating zone when compared to the industry standard 950 gauss interpole magnetic circuit.

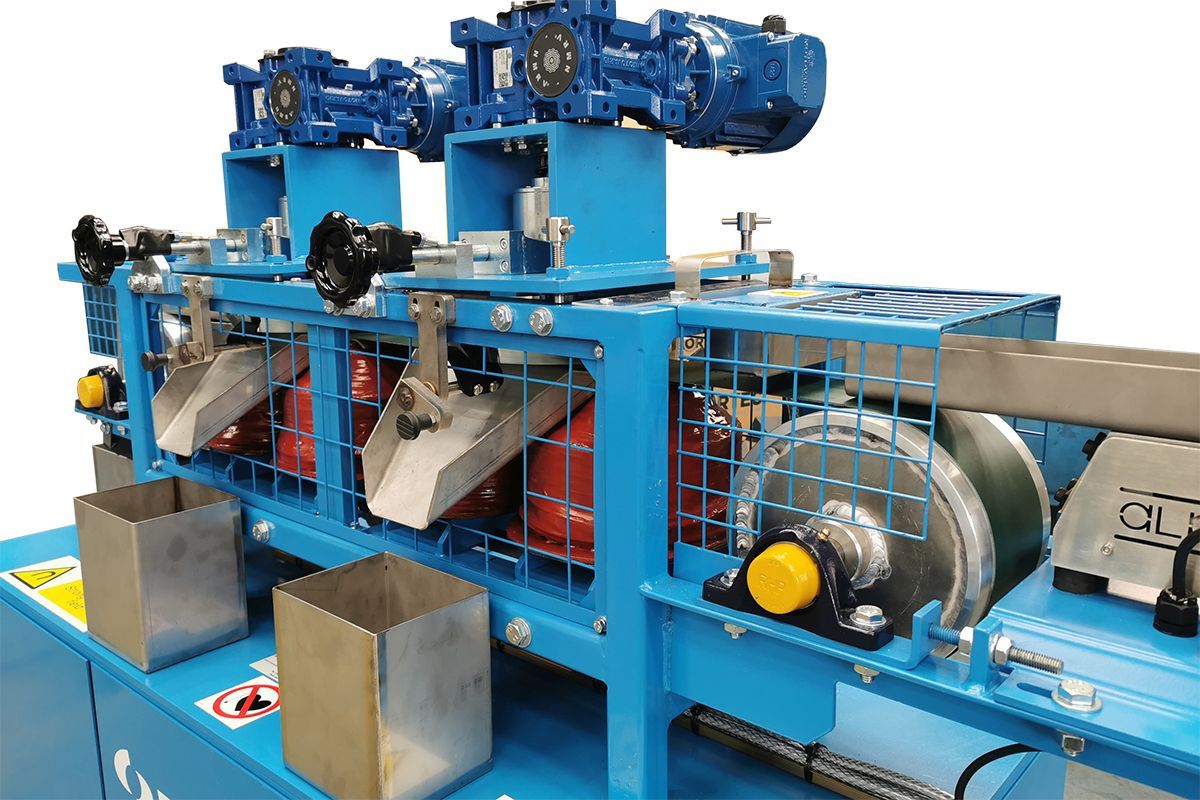

The new hybrid drum maintains the current layout of a standard wet drum and is identical to the widely known 950 gauss wet drum separator

The new hybrid drum maintains the current layout of a standard wet drum and is identical to the widely known 950 gauss wet drum separator

© Eriez

The hybrid drum, coupled with the self-leveling tank, maintains the current layout of a standard wet drum and is identical to the widely known 950 gauss wet drum separator. Upgrading existing 36- and 48-inch diameter wet drums to the Hybrid Wet Drum Separator is easily accomplished. The 950 interpole wet drum can be retrofitted without altering the existing tank or drive.

“Field results in iron ore concentration prove the superiority of these state-of-the-art separators,” says Eriez Director of Minerals and Materials Processing Jose Marin. “In fact,” he adds, “the increased recovery of magnetite in the rougher stage at an iron ore concentrator prompted the replacement of more than 20 48-inch diameter rougher units.”

According to Eriez, approximately two-thirds of the magnetic element in Hybrid Wet Drum Separator is constructed with rare earth magnets. The remainder consists of a transition section onto a ceramic element. This advanced design allows these stronger drums to properly discharge magnetite or ferro-silicon onto the concentrate launder without flow interference. Furthermore, the high-capacity design accommodates surges and fluctuations in the feed rate.

Optimizing magnetite recovery in the heavy media circuit requires properly sized self-leveling wet drum separators with agitating magnetic elements, including the addition of a hybrid element, according to Marin. The alternating polarity of agitating elements assists in releasing entrapped non-magnetic materials to attain maximum recovery and profitability. “The typical recovery of magnetite in a heavy media plant using traditional technology is expected at +99 %, while the anticipated recovery utilizing a Hybrid Wet Drum Separator is close to 99.99 %,” Marin explains.

Self-leveling wet drums incorporate a variety of features for straightforward operation, including a synchronous cog belt drive, greaseable bearings (during operation) and an oversized feed box.