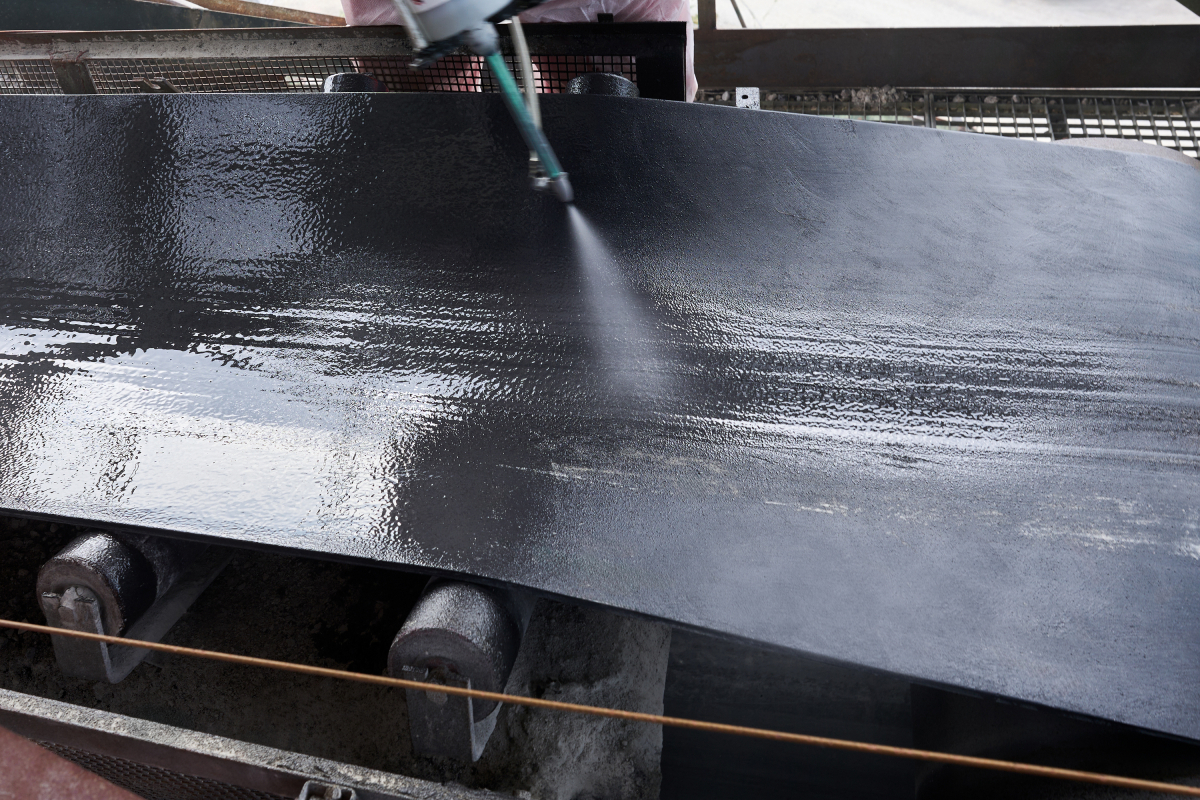

REMAREP SPRAY: Recoating conveyor belts instead of replacing them

19.11.2025Heavily worn conveyor belt cover plates usually lead to an inevitable belt change, bringing production to a halt and incurring high costs. With REMAREP Spray, REMA TIP TOP introduces an innovative system that quickly and easily repairs large areas of worn cover plates without the need to change belts with heavy equipment. This enables sustainable repairs that minimize downtime and reduce budget strain. The PUR-based coating system is easy to spray on and increases the resistance of wear-prone areas.

© REMA TIP TOP

© REMA TIP TOP

The product is ideal for large-scale renewal of worn conveyor belt cover plates and PU, PVC, and elastomer components. Thanks to REMA TIP TOP's innovative system solution, all that is needed is a pneumatic cartridge gun, cartridges, and a small, trained service team. After cleaning, roughening, and applying an adhesion promoter (SC4000 or NRX-MOD), the two-component, solvent-free polyurea coating system is applied in even layers. The coating cures quickly, remains flexible, and enhances the original surface properties. The sprayed-on coating seals the surface, increasing resistance to UV radiation, oils, and diesel fuels.

© REMA TIP TOP

© REMA TIP TOP

"When unplanned downtime occurs, every minute counts because each minute equals lost revenue," says Steven Tropp, Product Manager at REMA TIP TOP. “REMAREP SPRAY provides an immediate, uncomplicated solution when major damage occurs due to wear on conveyor belt cover plates. Thanks to its fast curing time, the system can be used again very quickly without removing the conveyor belt." REMAREP Spray seamlessly complements the portfolio of maintenance technologies, underlining REMA TIP TOP's mission to promote sustainability in bulk material operations, mining, heavy industry, and port facilities. Previously, the REMAREP ULTRA 10 casting application could reliably restore defective conveyor belts, but it was designed for smaller damaged areas. REMAREP SPRAY is a further development that selectively coats larger worn belt surfaces and effectively protects areas at risk of wear. Coating with REMAREP SPRAY significantly extends the conveyor belt's life cycle and closes gaps in time-critical processes. As long as the belt does not need to be completely replaced, REMAREP SPRAY enables multiple repeatable, economical repairs.

REMA TIP TOP provides customers with comprehensive service and support. Upon request, the technical team can assist with the initial application, train customer personnel, and ensure predictable maintenance costs and consistent product availability through regular deliveries of replacement cartridges.

REMA TIP TOP sees great potential in the future for further optimized, environmentally friendly systems with reduced VOC content or water-based systems. The company also sees potential in new fields of application where a perfect protective coating is required.