Sample division – the key requirement for first-rate analysis

05.09.2023A perfect sample preparation is the indispensable foundation for every analysis – because any errors will be reflected in the results later on. Therefore, the reliable creation of guaranteed representative subsamples plays an absolutely central role.

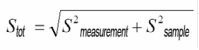

Today modern analytical instruments achieve previously unheard-of levels of precision. Verification limits of trace analysis in the ppm (parts per million) or ppb (parts per billion) range have now become standard. Unfortunately, it is frequently overlooked that the overall error in analysis is comprised of the measurement error of the analytical instrument plus the sampling error.

In other words: an error of 15% made in taking of the sample will never disappear irrespective of the precision of the measuring instrument. The error due to sampling becomes larger when, as is often the case, an analysis quantity of less than 200 mg is required and the original sample quantity available to the lab is, for example, 2000 g. For this reason, it is necessary to divide the total quantity into a representative sub-quantity. The aliquot should be representative and have the same physical and chemical properties as the whole quantity.

In other words: an error of 15% made in taking of the sample will never disappear irrespective of the precision of the measuring instrument. The error due to sampling becomes larger when, as is often the case, an analysis quantity of less than 200 mg is required and the original sample quantity available to the lab is, for example, 2000 g. For this reason, it is necessary to divide the total quantity into a representative sub-quantity. The aliquot should be representative and have the same physical and chemical properties as the whole quantity.

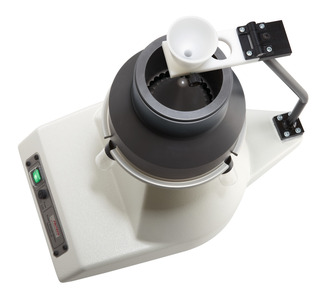

Rotary Cone Sample Divider LABORETTE 27 – with dividing head 1:8

Rotary Cone Sample Divider LABORETTE 27 – with dividing head 1:8

© Fritsch

The solution for optimal sample division

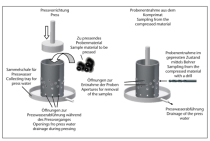

The Rotary Cone Sample Divider LABORETTE 27 from FRITSCH offers the ideal conditions for optimal sample division: The design is based on the combination of various dividing processes in one instrument. The sample is fed through a funnel to a dividing cone with a shape that allows for quartering and coning of the material. Against the surface of the cone, the sample material is accelerated outward through rotation of the entire system and divided by guide channels into 8, 10 or 30 individual material flows depending on the dividing head used. Due to the rotation of the dividing head, the number of dividing steps is increased up to 3,000 per minute, so that the final reduced sample is made up of a very large number of individual samples. Each with identical chemical and physical properties - and that 99.9 % precisely distributed around the statistical mean.

Sample feeding plays an essential role

The result of the sample division is more accurate the slower and more uniformly the sample is introduced. For this reason, we recommend use of the FRITSCH Vibratory Feeder LABORETTE 24. With rotary sample dividers of other manufacturers, the sample introduction just takes place eccentrically into the individual glass sample bottles. Unfortunately, this can result in systematic errors, when feeding materials with poor bulk and flow properties. The result is a reduced dividing accuracy.

Rotary Cone Sample Divider LABORETTE 27 – with dividing head 1:30

Rotary Cone Sample Divider LABORETTE 27 – with dividing head 1:30

© Fritsch

With the Rotary Cone Sample Divider LABORETTE 27, in addition to eccentric feeding directly via the guide channels, there is also the option of centric feeding of the sample via the central dividing cone, which prevents this error with poorly flowing, fine-agglomerating materials as well as with materials with high adhesive properties, and also enables optimal sample division of liquids. Through rotation of the cone, the flow of material is spread out radially and evenly over 360° and thereby also the random or systematically embedded properties of the sample. The result: representative subsamples that have exactly the same properties as the overall sample.

Operation and cleaning

Naturally, the handling and cleaning of the sample divider is equally important. The dividing head of the LABORETTE 27 can be very easily removed from the drive shaft in order to either clean it with a brush or remove it with compressed air. It is also possible to rinse it with water, place in an ultrasonic bath or wash it in a dishwasher.

Dividing heads for every material

Select exactly the right dividing head for your LABORETTE 27 as an accessory according to your application in the division ratios of 1:8; 1:10 or 1:30 made of stable POM plastic. Anodised aluminium dividing heads – 1:8 and 1:10 – are available for materials and suspensions with abrasive properties. And for especially aggressive solids and suspensions, the resistant PTFE-coated aluminium dividing head 1:30 is also available.

Conclusion

In order to take full advantage of the precision of modern analytical devices, good sample preparation is essential. For this reason, a modern analytical laboratory should use the FRITSCH Rotary Cone Sample Divider LABORETTE 27. Considering the very high investment costs for an analytical instrument, the cost of the LABORETTE 27 is easily justified. See in the video how the Rotary Cone Sample Divider LABORETTE 27 in combination with the Vibratory Feeder LABORETTE 24 make it easy to produce a representative sample.