thyssenkrupp Polysius supports SMA Mineral in pre-engineering for first industrial EAC pilot plant in Mo i Rana/Norway

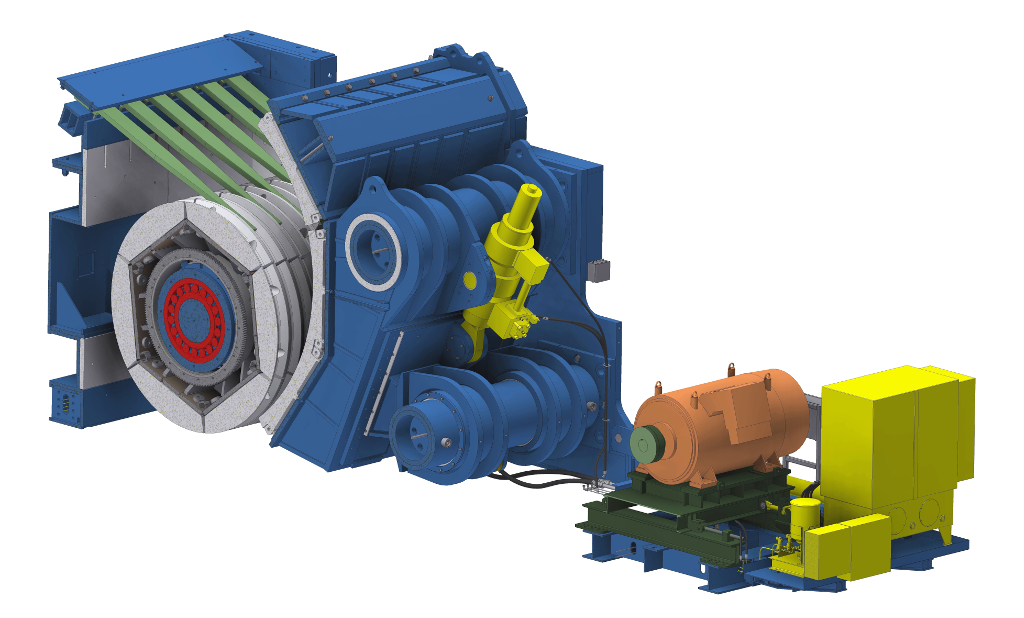

19.01.2026thyssenkrupp Polysius has been commissioned by SMA Mineral to develop the first industrial flash calcination plant using Electric Arc Calciner (EAC) technology in a pre-engineering phase. The focus is on the conceptual design and preliminary layout of the preheating and cooling systems, as well as the integration of SaltX Technology’s EAC process.

Aerial view at Mo i Rana

Aerial view at Mo i Rana

© thyssenkrupp Polysius

The initiative forms part of SMA Mineral’s long-term modernization program, aimed at increasing efficiency, reducing emissions and strengthening the competitiveness and resilience of Nordic lime production. Domestic production of lime and, in the longer term, fossil-free aviation fuel is critical to both industrial development and national preparedness.

As part of this work, thyssenkrupp Polysius and SaltX are developing a multi-stage cyclone preheater solution with cyclone-flash cooling, tailored to the structural conditions at the Mo i Rana site (Norway). This pre-engineering serves as the technical foundation for the planned pilot plant with a capacity of 120 t/d – a crucial step toward a potential future fullscale facility.

"With the start of pre-engineering, we move significantly closer to an electrified and climateneutral lime process,” says Sonya Fielding, CEO SMA Mineral. “Together with thyssenkrupp Polysius and SaltX, we combine technical excellence with industrial realization power. The pilot plant will be a milestone and a door-opener for a new era of quicklime production."

In parallel with the engineering work, SMA Mineral – in close collaboration with thyssenkrupp Polysius has initiated and financed a series of material tests to assess thermal behavior inside the cyclone preheater under electric process conditions. These tests, supported by SaltX Technology, provide essential technical data to validate and refine the key process parameters for the planned pilot facility.

“The material tests deliver crucial insights that directly influence the design of the preheating and cooling concept,” says Dr. Björn Olaf Assmann, Head of Innovation at thyssenkrupp Polysius. “They form the backbone of a robust next-generation calcination technology that can strengthen industrial performance while significantly reducing emissions.”

With this FEED study, thyssenkrupp Polysius strengthens its role as a key technology partner within the ZEQL project, supporting SMA Mineral and SaltX Technology on the path toward fully electric and emission-free quicklime production.

Through this partnership, SMA Mineral, SaltX and thyssenkrupp Polysius are accelerating the modernization of the lime industry and enabling a future-ready production chain that enhances both industrial competitiveness and long-term regional resilience.