Patented solution

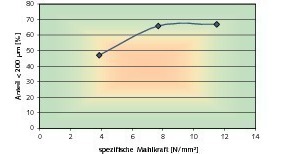

Fine grinding of wet cokeSummary: Fine grinding of coke is currently performed using dried coke, a factor which gives rise to extremely high operating costs. Dust Explosion Class ST 1 necessitates a complex system structure for existing grinding plants. The use of a high-pressure roller mill (compactor/granulator) for continuous grinding of wet coke provides a technical solution which eliminates the above disadvantages. Test results accord with the operating experience gained in a production plant, and provide a firm basis for safe and reliable plant design.

1 Introduction

Coke is the solid residue from the distillation, or carbonization, of hard coal, lignite, peat, wood or pitch. After quenching, the coke is crushed and graded into fractions. Metallurgi-cal coke, crushed (“cut”) coke and coke breeze are differentiated. The < 6 mm/8 mm fraction cannot be economically utilized without further treatment. Blends consisting of the above fractions with the addition of finely ground coke are prepared for special applications (Fig.1). The finely ground coke is produced from the not otherwise economically utilizable < 8 mm fraction.

After wet quenching,...