Advanced real time measurement technologies for the steel industry

Summary: Conveyed flow quality measurement in real time provides the next level of plant control where there is higher variability in composition than expected. Effective, proven solutions have been developed by analyser experts Scantech, one of the recognised leaders in the global minerals sector, that are successfully being implemented in the iron and steel sector.

Introduction

Real time conveyed quality measurement provides unique opportunities to improve process control. A number of proven technologies are used throughout the resources sector that provide significant improvements to existing processes by better measuring and managing bulk material quality. Scantech’s Rocks2data approach focusses measurement solutions to the quality of data required for optimal process control benefits rather than selling analysers based on their features.

Composition measurement can be performed using high specification Prompt Gamma Neutron Activation Analysis (PGNAA) for coal analysis in coke-making, sinter analysis in iron-making as well as scrap steel analysis in steel-making. Moisture can also be measured in coal and sinter using microwave transmission and in coke, sinter, magnetite concentrate, and scrap steel using fast neutron and gamma transmission.

All these technologies measure continuously through the full conveyed depth and provide results in real time directly to the plant control system and all analysis data is owned by the client. Remote access ensures onsite time is minimised and support is readily available if needed. All analysers can be installed during planned shutdowns and no interruptions to operations are anticipated throughout the life of the analysers which have no contact with conveyed flows and no wear components or consumable spare parts.

Quality variability

Material quality variability is a key challenge in process control. Despite mining, beneficiation and concentration processes, materials handling and blending there is still considerable variability when materials reach the next stage in the process. Iron ore, coal and scrap steel are typically received from multiple sources, each utilising their own quality control systems. Despite certificates of analysis there is usually significant quality variability within and between shipments received. Where bulk materials are sold on tonnage the risk is that moisture content has been added to increase weight. Quality variability is well accepted as having a major impact on process performance and managing quality requires appropriate high quality measurement systems, preferably those that minimise sampling error. Rather than taking more samples and not reducing sampling error, the smarter solution has been to measure quality continuous using representative technologies. Real time measurement is an obvious method to achieve this, with typically short paybacks, sometimes a few months and normally much quicker.

Conveyed flows represent the best opportunity to measure continuously as flow rates can be relatively consistent and material presentation to the measurement technology is ideal for penetrative analysis. High specification analysis systems are customised to each application to optimise the quality of the measurement data produced for the process control needs. Measurement of materials in stockpiles, hoppers, chutes or trucks is problematic for a number of reasons, mostly that no technologies will penetrate sufficiently to provide representative analysis and some systems interfere with material flow and can cause plant downtime so these are best avoided. Surface analysis technologies are appropriate for homogenised materials but these are rare in the resources sector. Coal, coke, iron ore, sinter and scrap steel will contain variable composition that is not reflected by the composition at a particular location on the surface of a stockpile or flow of material.

Representative sampling of bulk materials can prove unreliable due to segregation of materials by particle size, layering, or density variations and the required sample size and frequency to minimise sampling errors. Effective sampling is still required for analyser calibration and therefore a suitable sampling protocol should be developed to address these issues. Online analysers require calibration checks every six months so any sampling required can be made manageable through good planning and implementation and need not interfere with normal production.

Technologies – elemental analysis

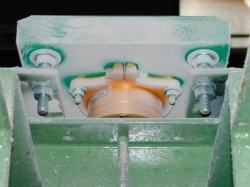

The elemental analyser range utilises high-performance PGNAA to measure the elemental composition continuously in real time, through the full conveyed cross section so that the entire flow can be representatively measured over short time increments. It is available in customised configurations for coal analysis for coke-making (COALSCAN 9500X), and for iron ore, sinter and scrap steel analysis (GEOSCAN-S). The system utilises a Californium-252 source to excite the elemental nuclei in the conveyed flow with neutrons, which in turn emit gamma rays that are detected by an array of high-specification bismuth germanium oxide (BGO) detectors above the conveyor, allowing individual elements to be measured directly and independently. This configuration, combined with proprietary software yields measurement performance that is unmatched. The higher specification is a combination of appropriate source size (which also determines shielding requirements for safety), number, configuration and type of detectors and digital multi-channel analysers (DMCAs) to optimise spectral response, and customised calibration to the material and composition range expected of the material being analysed. In Scantech’s experience over the last 25 years with PGNAA, BGO detectors have proved time and again superior to sodium iodide (NaI) in many ways. Signal quality, signal to noise ratio, peak to height ratio, higher crystal density, integrated DMCA configuration, stability, high linearity, self-verifying detector performance, and robustness (not prone to crystal damage through vibration or shock) have provided consistently improved performance over NaI detectors used previously.

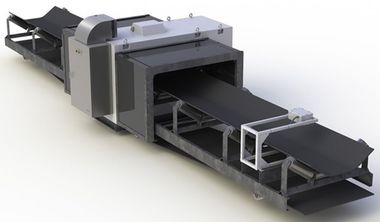

The GEOSCAN-S and COALSCAN 9500X are combined with Scantech’s TBM microwave moisture analyser (on suitable materials) and utilise a belt weigher input to calculate tonnage-weighted average dry basis elemental and moisture results over a short analysis period to the plant control system. The GEOSCAN-S can be configured to measure over shorter or longer time increments depending on the application. Where bulk sorting is required, short analysis, say every 30 seconds, provides optimal selectivity, whereas for blending purposes a longer measurement time of perhaps five minutes may be appropriate. Typically results are reported every 1 or 2 minutes with high accuracy due to the customised calibration for each material and application. The GEOSCAN-S has a patented no belt contact design and has no wear components, ensuring minimal maintenance requirements as well as complete safety through careful design of the shielding and access. No isolation area is usually required around the GEOSCAN-S during normal operation in most countries. Figure 1 shows a GEOSCAN-S on a sinter feed conveyor.

COALSCAN 9500X is the elemental technology used for blending coals prior to coke-making to ensure elemental and ash content is controlled. The ash content is measured to a better than 0.5 % total ash precision and individual elements such as sulphur, iron, calcium and others are measured accurately based on the customised calibration for the composition ranges expected.

Technologies – moisture analysis

PGNAA can be utilised to measure moisture using the hydrogen peak, however in some materials the total hydrogen is not indicative of the free moisture portion of the conveyed flow, and also because there tends to be a large hydrogen background due to shielding materials, which limits its usefulness. Typical precisions using the PGNAA for moisture content could be as large as 1 % moisture. The ratio of free moisture to inherent moisture is unlikely to be consistent so this method is not preferred for reliable moisture measurement in most applications.

TBM moisture measurement using microwave transmission allows coal, iron ores and sinter blends to be measured, typically to accuracies better than 0.5 % moisture. Attenuation and phase shift (group delay) are measured using microwaves transmitted through the full conveyed flow depth to indicate the presence of free moisture in the material. Moisture content can also affect the process performance and measurement may also assist with dust management or dry tonnage basis calculations.

The CM 100-S (Figure 2) measures moisture using fast neutron and gamma transmission in materials where the microwave technology is not suitable. T he CM 100-S effectively measures the hydrogen content directly to enable moisture measurement to accuracies of better than 0.3 % moisture over each measurement interval of a few minutes. It can be used for measuring moisture in magnetite iron ores and concentrates and coke. Many installations in Asian and Australian steel plants have proven very successful in coke moisture measurement.

Moisture analysis technologies are particularly useful for monitoring iron ores during loading onto ships where TML (transportable moisture limit) is useful to monitor. While not used for moisture certification of a shipment the real time analysis technologies are beneficial in detecting when material quality changes during the loading process and alternative actions are required to prevent the specification being exceeded. Moisture content also determines energy consumption in removing the water fraction. In coke-making this water is evaporated in the process, however quench water is added to the coke and its content is variable so measuring the moisture in the coke is valuable in controlling the carbon-to-iron ratio in furnace feed. Coke is very light relative to water so small variations in moisture content significant affect the weight of wet coke being measured.

Applications – coal, coke-making

Typical applications for these technologies in coke-making are in the blending of coals based on measured elemental content using COALSCAN 9500X. Coal is blended from multiple stockpiles as needed to attain the appropriate coke quality. Analysers can be used to create stockpiles during delivery and ensure blending flexibility as needed. Adjusting the blend in real time allows a more consistent feed quality to the process plant, improving its performance, as high variation leads to process inefficiencies. COALSCAN 9500X is also used in the coal industry for managing ash and sulphur content in thermal coal to improve environmental compliance of boilers. High and low sulphur containing coals are analysed and diverted to appropriate bunkers based on their composition. As well as the improved energy recovery from blended coal feed the real time analysis also results in improved environmental compliance and reduced sulphur dioxide emissions to atmosphere. Moisture analysis can also assist with coal handling and dust management. Coke moisture measurement using CM 100-S has proven very beneficial in Asian steel plants for carbon to iron ratios in blast furnace feed to ensure consistent pig iron quality.

Applications – iron ore, sintering, scrap steel

Scantech is the world’s leading supplier of PGNAA analysers to the iron ore sector with well over 50 successful installations with most major iron ore companies. Standard applications involve the measurement of iron ore quality each two minutes and the systems are located at mines to measure ore produced to reconcile with mine plans, on overland conveyors to divert direct shipping quality ore (DSO) to bypass unnecessary beneficiation, on process feed streams, on product streams, on discard streams, and on train and ship loading flows to manage ore quality throughout the mining, processing and materials handling stages. There is no reason that iron ore supplied to iron-making operations does not meet specification as the analysers are well accepted as the best solution for quality management. All GEOSCAN-M units are installed with TBM moisture analysers as standard.

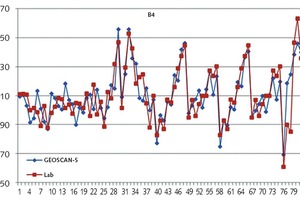

Sintering is a classic blending application where elemental analysis of the sinter for its key components, such as Fe, Ca, Mg, Si, Al, P, C, etc, can be used for blending control of the iron ore raw materials and importantly for basicity control through correct and precise limestone addition. A number of iron-making plants in Europe are utilising the high specification GEOSCAN-S to measure these elements with high accuracy and controlling sinter chemistry to within a narrow composition range to achieve optimal energy consumption, iron quality consistency, low basicity variation, and furnace availability. The use of high specification GEOSCAN-S has enabled B4 basicity (rather than just B2 using Si and Ca) measurement and control as the system measures aluminium and magnesium well (and P, etc.) compared to other PGNAA systems on the market. Figure 3 shows results of B4 basicity measurement comparing GEOSCAN-S analysis data to laboratory results. Typical precisions are in the range 0.05 B4 to 0.10 B4.

Moisture measurement using TBM has accompanied the GEOSCAN-S installations. The loss of control in sinter chemistry has been known to result in freezing of furnaces and significant cost in furnace remediation work and downtime causing lost production valued in millions of dollars per day. The addition of an analyser and improved sinter quality management can eliminate this risk. In such cases analyser payback can be measured in hours or even minutes.

High specification PGNAA can also be applied to scrap steel to determine purity and contamination levels so that these may be appropriately managed. CM 100-S can be used in scrap steel for moisture measurement.

Summary

Scantech PGNAA analysers are the highest specification available in the market and well proven in many industries. The customised approach to challenging applications has made the GEOSCAN the premium technology for representative real time elemental measurement in the minerals sector. Higher quality measurements (e.g. precisions) enable tighter process control and improved outcomes. Scantech’s philosophy of Rocks2data ensures that customised analyser configurations and calibrations produce the most useful, timely data possible to meet each client’s measurement requirements for effective process control.

Zero contact technologies are available for representative, high precision and frequent multi-elemental measurement as well as moisture measurement to ensure operations in the steel industry for coke-making, iron-making and steel-making can be suitably optimised. The application of these real time measurement technologies is proven to create more sustainability in operations by reducing energy and raw material inputs and increasing process efficiencies and product quality. Many of the world’s largest resources companies have adopted the technologies in various applications to not only improve sustainability but also to demonstrate responsible resource management to their stakeholders.

Authors:

Henry Kurth, Chief Marketing Officer and Minerals Consultant

Scantech International Pty Ltd, Adelaide/Australia, h.kurth@scantech.com.au

Henry Kurth has a degree in Geology from Queensland Institute of Technology (now QUT − Qld University of Technology) and has 15 years’ experience in mining geology roles in coal, gold and base metals operations. The next 7 years were in technical sales roles to the resources sector and the last 14 years with Scantech where he leads the global minerals marketing and sales functions in his current role as Chief Marketing Officer and Minerals Consultant. He has been a member of the AusIMM for over 35 years and is a member of the SME in USA and CIM in Canada. Henry Kurth has presented at more than 25 major minerals conferences and workshops on real time analysis technology applications.

Dr Luke Balzan, Chief Technical Officer

Scantech International Pty Ltd, Adelaide/Australia, l.balzan@scantech.com.au