DSIV: Day of pneumatic conveying technology

After the welcome by Jochen Baumgartner from the DSIV and the technical advisory board, the event started with a two-part lecture on the basics of pneumatic conveying technology once on the topic “How does a pneumatic conveying system work” – whereby the function and types of pneumatic conveying systems as well as the entry possibilities and the possibilities of pneumatic conveying were discussed. In the second part, the topics fluidizability of bulk materials, operating points of pneumatic systems and characterization of bulk materials were examined in more detail under the motto ”’Zoom‘ in the conveying line”. The two basic lectures were held by Prof. Dr.-Ing. Martin Geweke, Professor for mechanical process engineering at HAW Hamburg.

An important basic requirement for pneumatic conveying is the generation of compressed air. Filter systems and dryers systems are also used for the preparation of compressed air. Thomas Kuhn, product manager at Aerzener Maschinenfabrik GmbH, presented screw compressors as well as roots blowers in his presentation. Besides filter systems, refrigeration and adsorption dryers also coolers are used in case the hot compressed air cannot be cooled down sufficiently by the ambient air or heat has to be recovered as energy.

In pneumatic conveying systems, dedusting systems are mainly used to protect against dust leakage and to avoid dust explosions. There are different filter solutions for dry particle separation. Another important point is the correct design of the filter systems so that they do not become a bottleneck. Bernhard Voß, Sales Engineer Northern Germany, and Peter Richter, Project Manager (both Infrastaub GmbH) presented many interesting aspects of dust removal, the correct choice and design of filter systems and possible dangers from dust explosions to the participants.

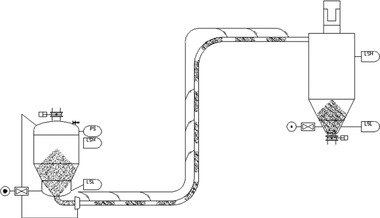

In pneumatic conveying, bulk materials are moved from A to B by means of gas as well as overpressure and negative pressure. There are various possibilities to feed the material into the pneumatic conveying line, such as screw pumps, pressure vessels, nozzle conveyors and rotary valves. In the lecture “Special conveying systems and their practical applications: Ceramic rotary valves in use” Mario Dikty, Branch Manager KREISEL GmbH & Co. KG, presented the possible applications as well as the advantages and disadvantages of ceramic rotary valves.

Also the following lecture of Thore Müller, Turnkey Sales Manager of Claudius Peters, on the subject “Energy-efficient pneumatic conveying with the FLUIDCON process” was held by Mario Dikty due to illness of the speaker. Besides the design and the mode of operation, the presentation also introduced reference plants such as the cement transport at Independent Cement in Australia.

The final part of the event was the presentation “Pneumatic conveying with pressure vessels and the TURBUFLOW®-Transport System” by Carsten Duwe, Head of Process Engineering and R&D, FLSmith Hamburg. After a very clear explanation of the basics and necessary requirements for pneumatic conveying of different bulk materials, Duwe presented the TURBUFLOW® technology including the Multi-TURBUFLOW®-Transport System. Specific examples were used to demonstrate the possibilities of energy saving and the economic advantages that these systems offer.

Of course, the personal exchange of ideas was also not neglected. The DSIV stands for the establishment of new professional contacts and the use of networks. After a very interesting and expert guided tour through the Speicherstadt, the participants spent the evening in the Fischerhaus. In a rustic Hanseatic atmosphere, the topics of the day were discussed in greater depth and further ideas were developed.

For the second day of the conference, a tour of the Moorburg power plant and, above all, the pneumatic conveyor systems installed there was planned, but due to existing restrictions, the conference participants were only able to view the power plant from the river side.

Not only excellent technical presentations and an intensive exchange of information about pneumatic conveying technology but also a lot of space for the mutual exchange of own experiences made this “Pneumatic Conveying Technology Day” a real highlight.

Further information on DSIV and the DSIV events can be found at www.dsiv.org.