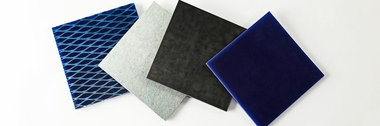

FerroCer® 22 extends overall equipment life

FerroCer 22 is the new cost-effective solution from FLSmidth that provides longer wear life than conventional panels. The unique matrix design of the panel construction combines the strength and malleability of steel with the superior abrasion resistance of ceramics. The result is a lighter weight, yet stronger wear panel that is ideal for smaller lump sizes than the original FerroCer. Weighing just 2.8 kg each means they are perfect in multiple mining and cement applications and areas that require light weight wear panels, such as chutes, hoppers and bins, guide and deflector plates, feed boxes, vibrating screen boxes and reclaimer and loader buckets.

The extended wear time provided by FerroCer 22 not only provides longer life and reduces the need for shutdowns to replace them but, due to their decreased weight, they reduce the load on equipment, meaning longer overall equipment life. Yet, FerroCer 22 panels generally cost less than half the price of competitors’ panels. FerroCer 22 panels meet all safety regulations for size and weight, and can be lifted by one person. Their compact shape makes them safe and easy to install using only standard hand tools, thus improving workplace safety. Each panel attaches using just a single bolt and nut. There is no need for heavy lifting or welding equipment, reducing production downtime. FerroCer 22 also offers a small environment benefit as there is less casting and freight involved compared to conventional wear panels.