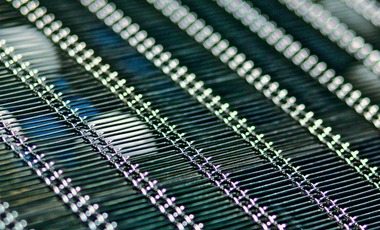

Self-cleaning screen panels for processing bulk goods that are difficult to sieve

Self-cleaning screen panels were previously available for openings of 2 mm to 28 mm. FLEX-MAT screen panels – made and marketed around the world by Haver & Boecker’s subsidiary Major Wire – expand the scope of application to finer materials with diameters to 0.5 mm and coarser materials of diameters to 100 mm. Due to their good wear properties, FLEX-MAT screen panels can be made with thinner wires than woven wire mesh. This increases the open screening surface and at the same time capacity and productivity, often up to 40 %.

Various series of FLEX-MAT screen panels allow fast availability of the right specification for almost any application. Series D and T, for example, have defined crimps that achieve almost the same separation precision as conventional wire screen panels with square mesh.

FLEX-MAT screen panels are offered in spring steel or stainless-steel versions and can be used on both side- and end-tensioned screening machines, and on all common modular systems. The polyurethane cross-connections are made customer-specific. Eleven production lines ensure fast delivery within the shortest possible time – worldwide.

Advantages compared to conventional screen panels:

High screening efficiency – up to 40 % more throughput

Long service life – up to 5 times more wear life

High profitability – high product quality, shorter downtimes, less maintenance cost

Hall 1 / 535

//www.haverboecker.com" target="_blank" >www.haverboecker.com:www.haverboecker.com