HAZEMAG Hammer Mills excel in terms of a high crushing ratio at simultaneously high throughput rates in soft and medium hard crushing

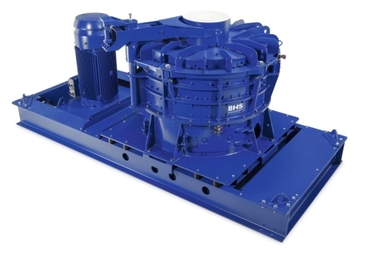

Summary: In the past the cost pressure caused increasingly high throughput rates of beneficiation plants at constant machine dimensions. This pressure will persist. Even larger beneficiation plants are to be expected in future, because the high-quality deposits have been exploited and as a result the raw materials quality in the ROM (run of mine) is getting worse. The solution consists in the reduction of the “totex” (total expenditures), that is in the use of smaller machine dimensions at the same or even a higher throughput rate with unchanged machine dimensions. The advantages of a higher performance level are the extension of the operating range and the development of new application fields [1]. HAZEMAG hammer mills offer this advantage of a high performance level at comparably small dimensions and are used across all sectors in different applications already today.

1 General information relating to grinding and combined drying and pulverization in HAZEMAG hammer mills

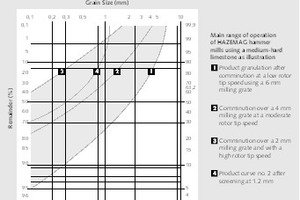

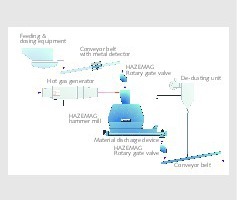

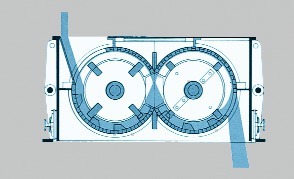

For crushing and simultaneously drying mineral raw materials – especially limestone, dolomite but also clays such as kaolin or bentonite are meant here – the single-rotor hammer mill series HUM, HUV or double-rotor HNM hammer mills are used. The RRSB grain size characteristic curves depicted in Fig. 1 describe the operating range of the HAZEMAG hammer mill that may be achieved in a simple pass. The grain size curves are average values for the processing of medium-hard limestone.

The products...