Innovative processing technology

Allmineral will present current projects and developments for the processing of sand and gravel, for recycling uses as well as for the mining industry at the bauma 2016.

Sand and gravel

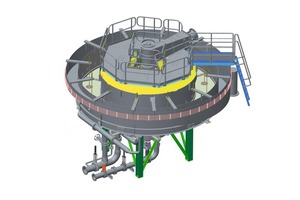

For more than 25 years allmineral is involved in the processing of building materials. Jig washers, type alljig®, and fluidized-bed sorters, type allflux®, have been installed in more than 350 sand and gravel processing plants. allmineral is continuously developing system solutions, amongst other things, in the field of sand processing. A sand processing plant located to the southwest of Berlin, which was commissioned recently, is a good example for the high product quality as well as for the systemic advantages of the current allflux technology as regards the operating costs and capital expenses.

Harmful organic constituents are removed from the screened, free-flowing sand in an allflux® fluidized-bed sorter without any additional pumps and cyclones. At the same time the sand is subdivided into fine, medium and coarse sands. The excellent precision of separation in sand processing enables the operator to offer a wide range of particle-size distribution curves to his customers as required – and this simultaneously with a maximum purity. Amongst other things, the comfortable control software of the allflux® fluidized-bed sorter essentially contributed to the fact that the complete sand processing plant could be commissioned within a few days only, immediately delivering reliably the specified product qualities.

Recycling

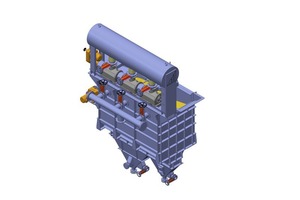

A current order to supply three air-pulsed jig washers to sort excavated material in Ticino is a proof of the efficiency and flexibility of the alljig® jig washers. The combination of these three machines separates coarse and fine feed material into four fractions of different density:

● Metallic portions, such as lead and other non-magnetic metals

● Mineral portions, mainly gravel and crushed concrete

● Bricks

● Organic materials and plastics

The jig washer design selected for this project combines many details from applications in other fields, such as slag, gravel and ore sorting. Furthermore, comprehensive series of tests in the pilot plant of allmineral ensure the process-engineering feasibility.

⇥Stand: B2.427