Moisture and more – the new MCT 460 and the bench top 466 Quik Check

The PROCESS SENSORS manufacture NIR technology which allows non-contact, nondestructive and in real time continuous measurement of moisture and other constituents.The NIR sensor can be installed on conveyors, chutes, and other transportation systems, measurements can be made through windows or with the use of our powder sampler where a sample is collected measurement made and the sample returned to the process stream and the cycle then repeated. The measuring heads are IP rated and are approved for dust Zone 22. The measuring instruments can be used up to an ambient temperature of 50°C in the standard version, with cooling options for higher temperatures. NIR photometry one takes advantage of the fact that many molecular compounds absorb light at specific wavelengths. Measure wavelengths change in intensity at the corresponding parameter and is proportional to the amount of this measuring component. In the measurement principle multiple reference wavelengths are used working with a measurement filter, the signals received at the detector are then offset against each other and output as calibrated display value. Advantages of the instruments include, temperature-stabilized detector, new measurement algorithms and advanced electronic processing. The sensors comeas standard with a 4 – 20mA analog output but the readings can also via common busses such as Ethernet TCP/IP, Profibus, Modbus however other bus systems can be used.

In addition to the Chemical, Pharmaceutical and Food industry, other industries such as Cement, Bio Energy and composting offers a wide range of applications for our instruments. In all these areas Process Sensors has already implemented hundreds of applications many of customers consider the advantage of NIR technology as is non-contact and so the sensor measurement area cannot be contaminated, or abraded away, high speed measurements and un complicated calibration.

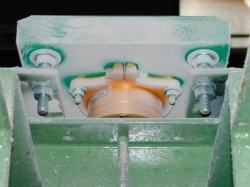

The bench top 466 model rotates the sample so to give a large measurement area and an average value for either accuracy or repeatability of non homogeneous products in seconds. Moisture analyzers from PROCESS SENSORS are known for their good results with high accuracy, robust workmanship at an affordable price.

Process Sensors have opened a branch in Germany in 2014. Close to Wiesbaden the office offers Sales, and application support. Contact: 0049(0)6434 9096955 or sent us a mail to

Halle 4A, Stand 202