New dust collectors: Performance Follows Shape

Small sizes with high filtration efficiency, low differential pressure, ease of use and maintenance: these are the advantages of the innovative dust collectors which are presented by Donaldson at the POWTECH 2016.

Focus on a new cartridge dust collector system will be displayed for the first time at POWTECH: The DOWNFLO® EVOLUTION (DFE) dust collectors. While cartridges are round, the development engineers of Donaldson have chosen a new shape. The great advantage of this innovation: The pulse cleaning has more filter area on the bottom of the cartridge. The dust can thus freely fall into the hopper. Users therefore benefit from improved cleaning and a lower pressure difference.

Also, the new design of the filter cartridges leads to significantly more compact dimensions of dust collectors and ultimately to an outstanding power density. Depending on the application, it can reduce the number of cartridges compared to usual cartridge filter systems by up to 30 %.

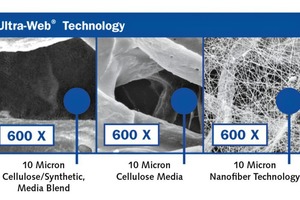

The DFE dust collectors reach also a high performance, because the Ultra-Web® filter technology (Fig. 1) with its nano finest fibres already holds back particles in the sub-micron range. The resulting filter cake can be removed by the automatic, compressed air-saving MaxPulse pulse cleaning system with high efficiency. In addition, the optimized flow of dusty air contributes to the extremely high power density through the filter housing. Easy maintenance is also convincing: the asymmetrical suspension yoke of the cartridge filters can be opened and closed without tools.

The practice-oriented development of the DOWNFLO® EVOLUTION dust collectors can be used in a wide spectrum from the pharmaceutical and food industry via the metal, cement and glass processing treatment to plasma cutting technology for volume flow rates from 2500 m3/h up to 150 000 m3/h.

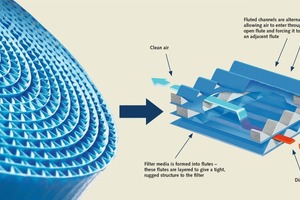

Another focal point of the exhibition program will be the PowerCore® technology. (Fig. 2) A new concept for silo venting filters that will be presented for the first time at a trade fair is an example of the versatility of application-oriented application possibilities. Since the installation and maintenance of large and heavy components of silo venting units is often cumbersome and expensive, Donaldson’s engineers have developed on the basis of the PowerCore® technology a compact silo venting unit with integrated filter packs that can be installed as full-featured plug and play unit (Fig. 3).

Hall 4, Stand 419

$(LEhttp://

$(LEhttp://