HAVER & BOECKER at ACHEMA 2024

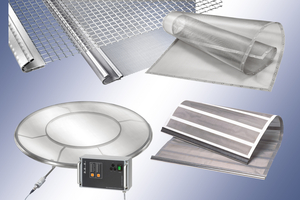

The Wire Weaving Division will be presenting the wide range and diverse applications of its woven wire cloth, filter weaves and laminates which are also used for highly efficient mechanical water treatment. In addition, there will be innovative and proven wire mesh products made of wire mesh: Filter elements and fabricated parts, POROSTAR® woven wire cloth laminated panels and filter elements in the compound, industrial screens and ultrasonic systems.

HAVER & BOECKER Machinery Division shows proven PumpPacker

The HAVER & BOECKER PumpPacker provides cost-effective and optimal filling of low-density products with a bulk density of 20 to 300 g/l such as silicates, resin, pigments and more into paper valve bags. The PumpPacker, available as an INTEGRA® enclosed packer or ELEMENTRA® stationary packer, is easy to install and provides smart operation that provides high weight accuracy and ideal compactness. With the proven packer, which will be equipped with the latest weighing electronics, HAVER & BOECKER is now closing a gap in its product range for lightweight materials.

The PumpPacker at ACHEMA has already been used by several customers worldwide and has proven its performance. Interested customers can reserve this machine at the trade fair for filling tests at their own plant.

Bespoke: The ideal bag design

Product, packaging, and machine technology are the so-called packing triangle, which forms a multivariable unit. The decisive basic for the design of the optimum filling technology and the customized packaging material is the product to be filled. In addition to the state-of-the-art packaging technology, the HAVER & BOECKER stand will feature a Tailormade Shop presenting the entire range of possible packaging as well as services related to the bags: From customized bag consulting to developing a bag design that matches the customer’s brand message to the sale of the bags, complemented by approaches to recycle the emptied film bags.

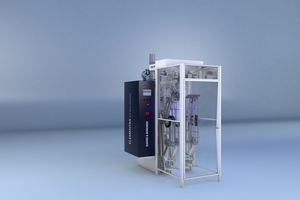

Feige FILLING presents the first fully electric filling system

Feige FILLING, a leading company in filling liquid and pasty products, has long pursued the vision of a more economical filling of liquids into drums. The company is doing just that with the introduction of the first fully electric filling system: the drum filling system ELEMENTRA 29 and its optional equipment variant FEIGE e-power. The electrically-driven system is more cost-effective than pneumatic-drive, compressed air options. The system is also equipped with the innovative FEIGE Web HMI, which enables quick orientation and easy operation with its intuitive touchscreen design. This increases productivity and shortens the training time for new employees.

AVENTUS showcases the swiftest bagging & palletizing line for LDPE

AVENTUS, one of the leading packaging specialists for free-flowing bulk materials, presents a cutting-edge model at this year’s ACHEMA show, showcasing the swiftest bagging and palletizing line for LDPE. In contrast to the displayed model the delivered line includes two bagging systems with a capacity of 50 t/h each, one conveyor belt, one palletizing system and one stretch hood system. The bagging systems are AVENTUS TOPAS SF featuring Form-Fill-Seal packaging technology and are capable of packaging up to 3000 bags per hour. The AURUM palletizer complements the full-line concept of high-speed bagging solutions. The ARGON stretch hood completes the packaging line, offering the greatest possible flexibility when using different pallet types and pallet dimensions. The line is an example of how AVENTUS ensures smooth and economical packaging operations by supplying machine solutions that are easy and intuitive to operate.

Transparency is the key – regardless of whether it concerns a single process step or the entire process. That is why all packaging and processing operations can be tracked by the AVENTUS production and data management systems. With the new one-in-all analytical tool – Q connect – the customers can gain unparalleled oversight of their entire production line’s performance.

QUAT²RO presents AI breakthroughs

QUAT²RO offers solutions for the digital management, control and analysis of processes, from packaging to logistics. The company’s new QUAT²RO® Valve Check and QUAT²RO® MatEx Check are AI-based products that enable users to achieve greater efficiency and productivity in their industrial packaging process. QUAT²RO® Valve Check ensures that each valve bag is placed perfectly onto the filling spout. QUAT²RO® MatEx Check combines expertise in valve bag filling with state-of-the-art AI camera technology to identify unusual material leakage during the filling process and stop the process to prevent further product loss. This minimizes product loss and reduces cleaning time. Booth visitors can test the functionality of QUAT²RO® Valve Check with an AI camera.

Additionally, QUAT²RO® Connect is introduced, an intelligent system that revolutionizes data analysis across the entire production. It centralizes machine data from all production facilities for easy access, laying the foundation for further customizable applications such as “Insights” and “Dashboards.” The platform provides cross-manufacturer insights into manufacturing status and is designed for future adjustments and compatibility with web-based devices. QUAT²RO® Connect combines efficiency, security, and scalability, ensuring robust, secure, and local performance with cloud-based management. In addition, the company will exhibit QUAT²RO® Production, a digital production management system, and a new version of the batch management system, QUAT2RO® Batch.

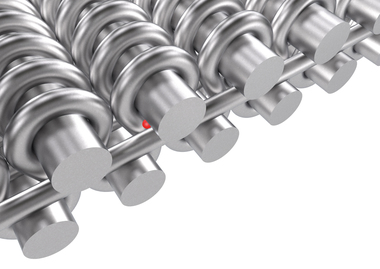

HAVER & BOECKER Wire Weaving Division presents innovative metal meshes

Conventional filter mesh with small pore sizes lead to reduced flow rates and considerable pressure drops in the production process. A weaving technology developed by HAVER & BOECKER creates a three-dimensional pore geometry that offers filtration properties that cannot be achieved with conventional woven metal filter media. This makes industrial filtration processes faster, safer and more efficient. Visitors to stand B86 in hall 5.0 will be able to find out about the product range and possible applications of metal meshes, filter weaves and laminates for highly efficient mechanical water treatment: Filter elements and fabricated parts, POROSTAR® wire mesh laminates and filter elements, industrial screens and ultrasonic systems.

Live presentation takes place daily at 11.00 h in German and at 13.00 h in English language.

NEXOPART

The young joint venture between the HAVER & BOECKER Wire Weaving Division and Hosokawa Alpine will be presenting its products and measuring equipment for particle analysis to determine particle size and particle shape at stand A20 in hall 12.0. The portfolio includes products and services for analysis and laboratory technology, from sample splitting and sieve analysis to dynamic image analysis.

Hall 3.0, Stand F38:

HAVER & BOECKER Machinery Division

Hall 5.0, Stand B86:

HAVER & BOECKER Wire Weaving Division

Hall 12.0, Stand A20:

NEXOPART