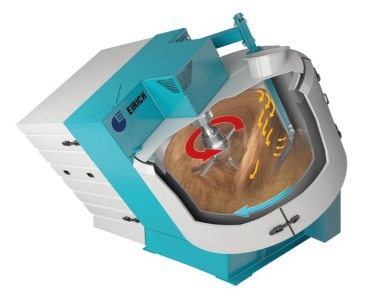

Maschinenfabrik Gustav Eirich GmbH & Co KG

The one-pot process, which thanks to the Eirich mixing principle enables mixing, kneading, granulating, and coating in a single machine, forms the basis from which the company offers innovative developments that impress with digital applications and smart features.

World-first presentation of an innovative new laboratory mixer

Eirich will be presenting the world premiere of its impressive new generation of laboratory mixers, which can be used in a wide range of applications with state-of-the-art control systems. The new EL5 Mixer is smaller, more lightweight, and smarter than its tried-and-tested predecessor – and this with the same high levels of performance and robustness. It impresses with easy operation, scalability, integrated tilt adjustment, and well thought-out options for day-to-day laboratory operations. These include recipe management, data collection, and network capability. The new 5-liter machine rounds off the existing portfolio of the Eirich range of laboratory mixers. “This machine is not only extremely cost effective, but also comes with all the most important features as standard. This makes it the perfect point of entry into the world of Eirich, while the all-rounder C5 offers numerous additional features that place it squarely in the premium segment. Whatever the requirements, our product range now offers the perfect solution for every challenge,” explains Tobias Lang, Product Manager at Eirich.

Smart quality systems – autonomous analysis and process assistance

In its digital solutions for process optimization, Eirich uses autonomous analysis tools, AI-based process assistance systems, and – as a brand new feature – product characterization with deep learning. QualiMaster VC1 was already presented last year as a specialist solution for granulation and is equipped with a special camera that continuously records, processes, and analyzes images from the product conveyor belt. In the process, the system identifies and calculates numerous parameters and product properties from the images. In the process, the assessment of the quality parameters can be performed by the person operating the system, or this can be handled by intelligent control algorithms.

In addition to this, Eirich will also be presenting the new QualiMaster VC2 for the first time at Powtech. This features a universal camera system for automatic trend detection via AI-based image analysis, thus making it a universal instrument for quality assessment of materials of all types and consistencies. The smart quality system takes images of the product on the conveyor belt immediately downstream of the mixer. Based on the images, a decision is then taken whether the condition and consistency of the material matches the requirements, or whether undesirable trends are evident in terms of the material properties. In contrast to the VC1 system, VC2 does not measure any concrete values or parameters from the images, but instead uses deep learning – a sub-area of machine learning – to compare the actual results against reference images. One element that makes this possible is so-called neural networks, which are a form of self-learning algorithms. The more extensively the neural networks are trained on the relevant properties of a sample, the more precise the detection results become. As a result, quality control systems benefit from reliable and consistent classification of the investigated products. This makes it possible to analyze the materials in the process. The data obtained in the process can be used as a basis for intelligent closed-loop control processes that are capable of self-optimization. The goal of Eirich is to enable so-called “dark factories.”

LogLizer – an all-in-one system

Another highlight at the trade fair booth of Eirich is the company’s new LogLizer system. This turnkey all-in-one system for recording, processing, and analyzing process data of all kinds is preconfigured and can be set up in the line in a very short space of time. Data sovereignty is ensured at all times. In addition, machines and sensors from third parties can also be incorporated in order to represent entire, integrated processes and recognize connections and interdependencies. All process data is processed in a high-performance computer and saved in a database. The familiar “Eirich ProView” display and analysis tool is used for visualization. This web-based system can be used flexibly with a PC, tablet, or smartphone. Direct access to real-time or historical data is also possible.

Stephan Eirich closes with this: “We are really looking forward to meeting and talking to people who are interested in our systems, and we will be able to demonstrate at the show the full scope of our products and solutions – ranging from laboratory mixers and AI/deep learning offerings to technology for manufacturing electrode mixtures for Li-ion batteries.”

Booth 4A-403