Niagara F-Class enables 24 vibrating screens in one building –

without structural reinforcement

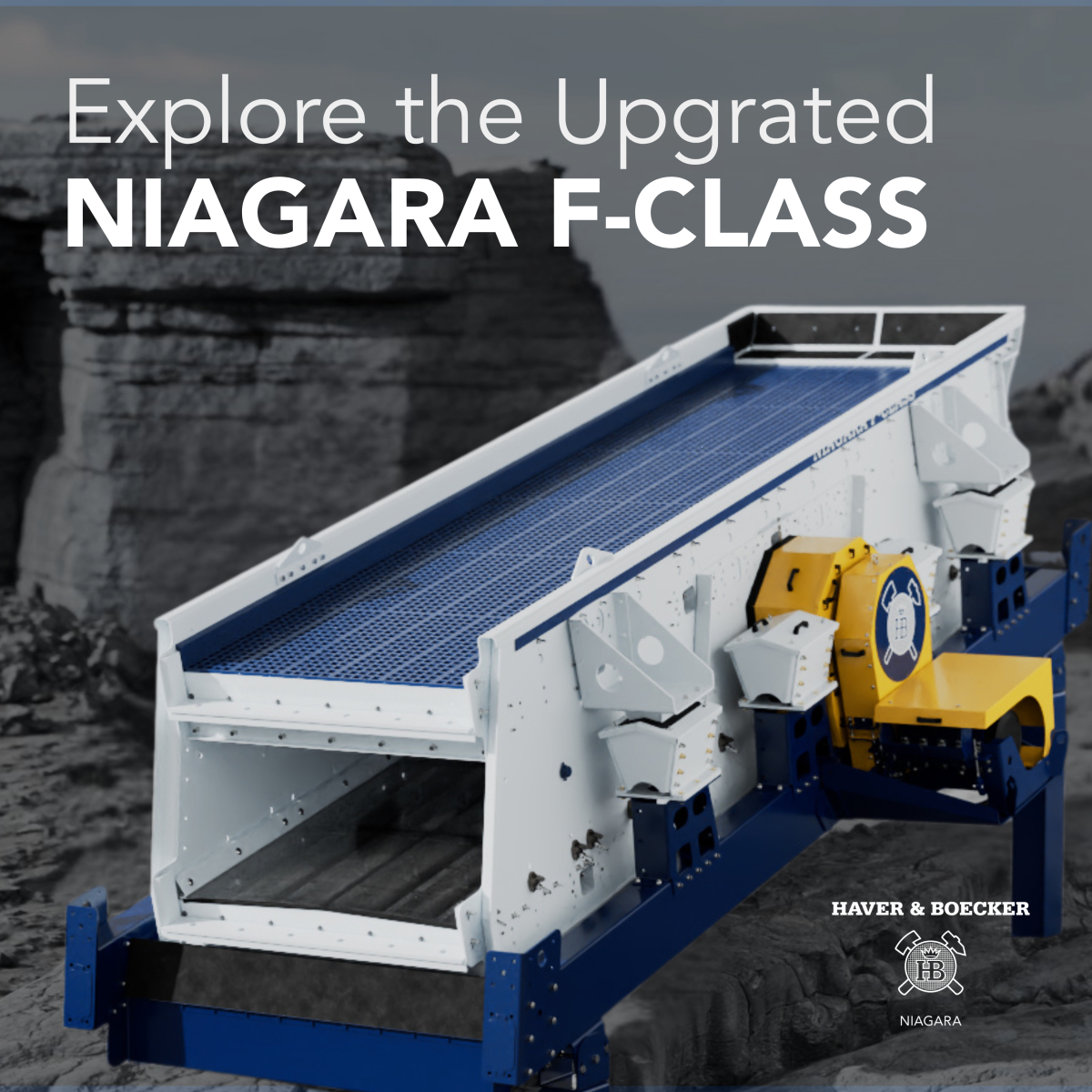

Upgraded Niagara F-Class

Upgraded Niagara F-Class

© Haver & Boecker Niagara

The upgraded Niagara F-Class from Haver & Boecker Niagara addresses this challenge directly. The company engineered a screening system that achieves technical balance – literally. The double eccentric shaft creates a constant stroke maintaining g-force while handling dynamic loads, and the counter weights generate equal forces for a dynamically balanced system, transmitting virtually no vibration into the chassis. This provides an exceptional level of structural stability, allowing multiple machines to run side by side without requiring major foundation reinforcement.

In fact, hundreds of Niagara F-Class machines are already operating successfully across North America and other regions worldwide – reliably delivering high-capacity screening with minimal structural impact. With this upgraded generation, Haver & Boecker Niagara is now bringing this proven technology to the European market, offering plant operators a solution that combines structural stability with scalable performance.

The challenge: Structural load limits in multi-screen applications

A processing plant operator required the installation of over 24 vibrating screens within a single facility footprint to meet increasing production demands. However, the building’s structure was not engineered to handle the dynamic loads typically associated with such a high concentration of screening machines. Conventional solutions – such as isolated foundations or structural stiffening – would have imposed significant cost, complexity, and downtime. A mechanical solution was required: reduce the vibrational force transmission at the source.

A real-world scenario: Over 24 machines,

one building, zero structural stress

Video: Niagara F-Class

Video: Niagara F-Class

© Haver & Boecker Niagara

In response, Haver & Boecker Niagara deployed the upgraded Niagara F-Class within a single high-load processing building. Traditionally, such a setup would raise concerns about cumulative vibration loads, structural resonance, and long-term wear on the foundation.

However, the F-Class’s double eccentric shaft assembly combined with its dynamically balanced design ensured that vibration transmission to the structure remained negligible – even under full operating loads. The result: a fully functional multi-machine setup without vibration isolation or foundation reinforcement, or structural retrofits. This installation is not theoretical. It operates daily, handling fluctuating material loads and delivering consistent throughput – while the building remains vibration-free.

Onsite monitoring confirmed that vibrational energy remained confined to the individual screen units, validating the dynamic balancing and mounting system. No structural retrofitting was required, and the system was commissioned without modification to the original facility. Despite the high machine density, no dynamic overloads, resonance conditions, or structural fatigue were observed.

The engineering behind stability:

Key upgrades in the Niagara F-Class

The engineering response was the upgraded Niagara F-Class, a vibrating screen specifically enhanced to minimize external dynamic forces while maintaining throughput performance. The core of the F-Class stability lies in three key engineering decisions:

Double eccentric shaft assembly

The F-Class employs a double eccentric shaft system that maintains a constant circular stroke. By maintaining a constant circular stroke, the F-Class ensures consistent g-force output, which is critical for material stratification. More importantly, the eccentric counterweights rotate in a way that cancels out lateral and vertical force peaks. The counter-rotating eccentric masses are configured to generate internal motion while cancelling net dynamic force transmission to the supporting structure.

Shear rubber mounts

The machine is supported by using shear rubber isolators, which replace conventional helical springs. These mounts absorb both vertical and horizontal accelerations, substantially reducing vibrational energy transferred to the support frame and surrounding structure.

Stationary base frame integration

The frame was redesigned to serve as a stable interface between the screen box and surrounding infrastructure. Its static base allows direct integration of multiple units side by side, including service platforms, feed systems, and enclosures – without requiring dedicated foundations. The machine’s frame is designed to accommodate structural integration – whether in a new-build or retrofit. It supports custom platforms, hoppers, and dust enclosures while maintaining minimal structural vibration.

To reflect on the engineering achievement, Klaus Fennenkötter, Engineering & Technology at Haver & Boecker Niagara Germany, notes: “The key to this development was not just reducing the vibration – but designing a vibrating screen that actively protects the structural integrity of the entire facility. With the upgraded F-Class, we can confidently place dozens of machines in one building without compromising safety or long-term reliability.”

From vision to execution

Beyond the engineering challenge, this project also represents a long-term strategic goal realized. As Dr. Metodi Zlatev, Head of Sales and Project Department, explains: “We had a clear vision: to overcome one of the industry’s biggest limitations – structural vibration in high-capacity screening setups. It took years of focused development and collaboration between our engineering and field teams, but today the upgraded F-Class turns that vision into reality.”

These combined technical and strategic efforts culminated in a screening solution that is both high-performance and structurally neutral – and scalable by design.

Supporting design features

While the structural stability was the critical focus of this installation, the following design elements contribute to long-term operational performance:

Weld-free, lock-bolted frame: Increases fatigue resistance and allows fast service access

Modular deck configuration: supporting various screen media like wire mesh, polyurethane, and hybrid configurations and quick change-outs.

Pulse Condition Monitoring: Enables predictive maintenance through real-time sensor feedback and Pulse Vibration Analysis (VA) for field diagnostics.

Drop Guard System: Tool-free, polyurethane-lined protection of structural members against abrasion

Ty-Rail™ quick-tensioning system: Reduces media change time by approximately 50 % compared to conventional clamping

In addition to structural and mechanical design improvements, the upgraded F-Class also delivers measurable benefits from a service and maintenance standpoint – as noted by the Head of Haver & Boecker Niagara’s service department Lothar Gillenkirch: “From a service perspective, the upgraded F-Class is a major step forward. The minimized structural impact not only protects the building but also reduces long-term machine wear. Combined with predictive monitoring and tool-free access, it simplifies maintenance and maximizes uptime.”

Conclusion

The upgraded Niagara F-Class is more than a vibrating screen – it’s an integration-friendly, structurally neutral screening solution. By minimizing external dynamic loads through synchronized eccentric motion and shear-mounted isolation, the machine allows for multi-unit deployment without structural reinforcement – enabling scalable throughput without compromising building integrity. Its performance is not just measured in throughput and separation accuracy, but in how quietly and safely it fits into the plant environment – even in multi-machine applications.

With field-proven installations operating more than 24 machines within a single structure, the F-Class offers a tested path to scalable, low-maintenance screening without compromising building integrity.