Report on Nordmineral Recycling GmbH & Co. KG, Dresden

Editor-in-chief Dr. Petra Strunk and Dr. Brigitte Hoffmann, representing the editorial team of AT MINERAL PROCESSING, were given the opportunity to visit the plant for a factory report. Managing Director Stefan Becker and Plant Manager and Authorized Signatory Dipl.-Ing. Knut Seifert provided information on behalf of Nordmineral.

History of the recycling plant

The Nordmineral site is located in the area of the largest inner-city sand pit of the former building materials combine of the GDR. In 1994, the city of Dresden issued a statute that was almost revolutionary at the time, imposing a so-called “delivery obligation” on waste producers for the large quantities of construction waste generated during the construction boom after the fall of the Berlin Wall. At the same time, the city commissioned four privately operated facilities distributed across the city and built specifically for this purpose to accept waste on behalf of the city under a 10-year contract. The aim was to maximize the recovery of recyclable materials through processing and returning them to the economic cycle. One of the facilities was built in Heller.

The system worked successfully for two years. Then the federal legislature passed the first Circular Economy Act, which deprived municipalities of the option of continuing to keep construction and commercial waste under the delivery obligation. The facilities contracted by the city were now in open competition, mainly with open-cast mining fillings. However, their acceptance prices were so far below those of the plants that considerable economic problems soon arose. In 2000, the then operator of the plant at Heller also threw in the towel. Regardless of the undoubted continuing difficulties, the Amand Group continued to believe in the future of building material recycling. It seized the opportunity to take over the Heller site – and continues to operate it to this day.

Technical history

The processing plant at the Hammerweg site began operations in May 1996. It still stands there today in virtually the same form as when it was first built. The classic processes of “crushing, screening, and sorting” still form the core of the plant. This is not due to corporate cost-cutting measures, but mainly to the fact that nothing significantly new, let alone revolutionary, has been developed for the processing of mineral waste in the past thirty years. However, major changes to the plant technology were hardly necessary because, from the outset, the plant contained almost everything in high quality that still represents the state of the art today.

The quality of the plant makes it possible to produce certified RC chippings in all common grain sizes from broken concrete and bricks. These chippings can be used in numerous industrial applications, such as fresh concrete and liquid floors.

Concrete and brick aggregates have always been popular with construction and other manufacturing companies. Concrete aggregates, for example, have specific technical advantages over the primary building material gravel in certain applications. Brick aggregates are very well suited as a component of roof substrates, which Nordmineral manufactures and sells ready for use, due to their ability to store water, among other things. The same applies in principle to a range of aggregates from mixed fractions. However, according to Nordmineral officials, their use is currently suffering as a result of the Substitute Building Materials Ordinance. This has significantly tightened the chemical requirements for aggregates and also created new bureaucratic hurdles that do not apply to primary building materials.

When processing broken concrete and used bricks, between 30 and 50 % sand is technically unavoidably produced, for which there is still a lack of suitable applications. Nordmineral is therefore looking for ideas on what else could be done with the sand other than eventually filling it somewhere. To this end, it is drawing on the close relationships it has cultivated over many years, particularly through Knut Seifert, with technical universities in the region. Whether TU or HTW Dresden, Bergakademie Freiberg or BTU Cottbus-Brandenburg, Nordmineral has supported and continues to support projects with all of these universities.

Special features of recycled building materials

In Germany, 188 million tons of the approximately 208 million tons of all mineral construction waste were recycled in an environmentally friendly manner in 2022, which is more than 90 % for the first time. While only just under 87 % of excavated soil (around 59 % of the total volume) was recycled, the recycling rate for granular mineral construction waste, such as building rubble and road construction waste, was just under 96 %. The substitution rate of granular mineral waste processed into recycled building materials for primary aggregates was 13.3 % (75.3 million tons) [3]. Of these recycled building materials, just under half went into road construction (35.8 million t) and 14.5 million t (19.3 %) went into concrete and asphalt production. A rate of 13.3 % may sound low, but the substitution rate depends on the total demand for aggregates and the amount of waste generated. No more than 100 % of waste can be recycled.

Nevertheless, the efforts of the construction industry to promote a sustainable circular economy are sensible and necessary in order to produce higher-quality recycled building materials and find new ways of recycling. In many areas other than those mentioned, the use of recycled building materials is already technically possible today if the political framework conditions are created in line with the circular economy concept. In particular, the qualities of recycled concrete and brick allow these secondary building materials to be used in high-quality applications. Mr. Seifert explained the difficulties that producers have to deal with in this regard using impressive examples.

However, the use of RC building materials is also technically possible in other areas if the political framework conditions are created in line with the circular economy concept.

Let’s mention just one of them. The Infineon Technologies AG semiconductor plant in Dresden is currently being expanded. During the excavation of the construction pit, six-figure volumes of rock were produced. Nordmineral wanted to process this rock so that it could be used as an aggregate for the fresh concrete to build the foundations of the project. This is essentially an ideal example of the concept “From the city – in the city – for the city.” It is also advantageous from an ecological point of view, as it would have reduced transport distances to a fifth. The city thwarted this because the rock from the excavation pit becomes legally classified as waste simply by being excavated. This “waste” would have had to be temporarily stored to bridge the “time lag” between excavation and reuse as aggregate. Temporary storage facilities for waste are subject to approval under the Federal Immission Control Act – temporary storage facilities for natural building materials, incidentally, are not. The city was not prepared to grant even a temporary permit.

Facts such as these explain why both the BDE (Federal Association of the German Waste Management Industry) and the BRB (Federal Association of Recycling Building Materials) have been calling for years for the public sector to take a proactive leading role in the sustainable procurement of substitute and recycled building materials.

Although the position is not fundamentally controversial politically, the federal legislature has not taken any legal action that would actually help. The Substitute Building Materials Ordinance (EBV), which took almost 20 years to come into being, has so far done nothing to increase the use of RC building materials. On the contrary, its cautiously worded bureaucratic sophistication is leading to a mass exodus from what was actually intended to be high-quality building material recycling. In 2019, the Free State of Saxony created a welcome and clear obligation for public contractors to use recycled products with Section 10 of the new Saxon Circular Economy and Soil Protection Act. However, most administrations simply ignore this obligation, mainly for formal legal reasons.

The control regulations that manufacturers must comply with are proving to be a major obstacle to the use of RC building materials. There is a significant difference between natural stone products and recycled building materials in this respect. Only in the case of the latter is the effort required to prove suitability, comply with quality parameters, and provide detailed documentation of their use so considerable; in the case of natural stone products, on the other hand, none of this is necessary. With prices mostly being similar, it is not surprising that private and public clients simply shy away from the additional administrative effort that the use of RC materials inevitably entails.

The goal: high-quality recycled building materials

For a whole series of reasons that become obvious on closer inspection, the idea of a “regional circular economy” has recently been gaining more and more supporters. Stefan Becker coined the slogan “From the city – in the city – for the city,” which was briefly mentioned above. When asked what this means, he replies: “It is hopefully a memorable slogan for the simple proposal that the waste generated in a city like Dresden should also be processed in the city and the resulting RC products should also be used in the city. “ Knut Seifert adds: ”Recycling begins with the consideration – can I continue to use something, or can I repurpose it, and only then does the more or less complex processing for the production of recyclates come into play.” It is clear from his words and from what you see in the company that this basic idea of the circular economy is put into practice (e.g., the use of precast concrete parts delivered as construction waste, often only slightly damaged, as barrier segments for material storage).

The company on Hammerweg produces around 55 000 t/a of qualified mineral recycling building materials, including high-quality substrates, construction waste recyclates, decorative chippings, and roof and soil substrates. Recently, liquid soils in accordance with RAL GZ 507 have been added to the range.

Processing method

The original operator of the plant had its roots in the extraction and processing of rock. This also explains the solid construction, which would be designed differently in many respects (e.g., in terms of energy efficiency) according to today’s standards. However, it is precisely this construction method that is a major reason for the unusually long service life.

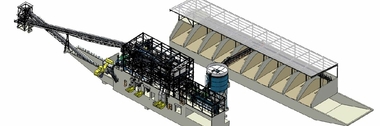

One of the regulatory requirements for the construction of the plant was that the machine configuration had to be housed in a closed hall. The plant components correspond to those of a conventional construction waste recycling plant. The delivered material is first stored outdoors, sorted as far as possible; customers are encouraged to deliver sorted material. This pre-sorting is very important for the subsequent mechanical processing. If necessary, an excavator removes large foreign objects or impurities. A wheel loader then fills the material into a feed hopper. The material is transported via a heavy-duty conveyor belt with pre-screening and magnetic separator to an impact crusher, where it undergoes further magnetic separation and screening (vibrating screens). If the material is contaminated, the material flow can be diverted to a manual sorting cabin with eight sorting stations, where smaller impurities are sorted out before the material is transported via an elevator to a triple screen with integrated wind sifter for further classification. This is used to separate the light fraction, mainly wood and fibers. This light fraction can be used for the production of substitute fuels at the Amand plant in Lockwitz.

Knut Seifert points out that the screening technology used is the biggest difference compared to most mobile plants and is crucial for the quality of the end products. It ensures that the grain sizes required and expected by industrial users are reliably maintained.

The individual fractions are stored in boxes, either in the hall or outdoors, depending on the material, and are then available as RC sales products.

The current output of the recycling plant is 120 – 130 t/h, although it is designed for a higher throughput. In order to achieve this without any loss of quality, the plant would need to be modernized. According to Knut Seifert, plans for this are in place. However, their implementation would require a significantly higher, sustainable demand for recycled building materials from the construction industry.

Liquid soil plant according to RAL 507

The company recently commissioned a plant for the production of liquid soil, thereby expanding its product range. Given the large amount of excavated soil that can no longer be deposited in landfills under the KrWG, the so-called RSS® process [2] is particularly interesting, as it allows the reuse of soil waste and saves energy and thus costs. By adding various compounds such as bentonite and cement as well as process water, a self-compacting, temporarily liquid soil is produced, which is used as backfill material in appropriate construction projects (installation of underground components). Studies conducted in collaboration with FiFB Leipzig have shown that the sand produced during the recycling of concrete and bricks can also be used to produce liquid soil. This makes the purchase of the Type 5.2 compact plant worthwhile for Nordmineral, as sand is one of the fractions that is difficult to market and becomes a cost factor. As there are also major advantages on the construction site where the liquid soil is used (CO2 savings, lower energy consumption), this new pillar is a further step by the company to implement the circular economy concept, save resources, and contribute to environmental protection.

Thanks

The representatives of AT MINERAL PROCESSING would like to express their sincere thanks for the opportunity to visit the company and wish it continued success and a rethinking of politics and economics with regard to the use of recycled building materials, thereby improving sales opportunities for RC building materials. In this regard, the legal regulation on the end-of-waste status proposed by the Federal Ministry for the Environment would certainly also serve this purpose. The German Construction Industry Association considers this to be a decisive lever for the increased use of recycled materials. It is not only Nordmineral that hopes that such an end-of-waste regulation will soon be implemented.

Authors:

Dr. Brigitte Hoffmann, Consulting Kreislaufwirtschaft/Umweltschutz, Oberschöna/Germany

Stefan Becker, Geschäftsführer AMAND Umwelttechnik, Dresden/Germany

Literature

[1] 14. Monitoring-Bericht zum Aufkommen und Verbleib mineralischer Bau- und Abbruchabfälle. Mitteilung der Initiative Kreislaufwirtschaft vom 06.12.2024

[2] https://www.baumagazin-online.de/d/fifb-neue-wege-im-mineralstoffrecycling/